Index to Demonstrate Modular Eight-spindle Automatic CNC Turning Machine at PMTS 2015

Index will demonstrate its MS22C-8, a modular eight-spindle automatic CNC turning machine, producing brass connector parts at PMTS 2015, Booth 400. The MS22-8 is designed for fast parts machining capability, especially highly complex parts.

The Index MS22C-8 has many applications, from automotive to medical technology. It also produces small batches efficiently and economically. The INDEX MS22C-8 can be bar-fed or loaded with chucked parts.

The machine can be configured to operate as an 8-spindle machine, a double 4-spindle machine, dropping two complete parts at a time or a machine with double rear-end machining. The MS22C-8 in double four-spindle mode actually runs as two machines working with one another simultaneously on a single base. Every second tool station always has simultaneous access to the same tools.

The MS22C-8 can accomplish turning, off-center drilling and thread cutting, inclined and cross-drilling, milling, multi-edge turning, hobbing, tooth milling, deep-hole drilling or slotting. Another benefit for the user is that all standard tool holders and tool holder system interfaces can be used with a range of popular adapters (Capto, HSK, VDI, INDEX systems).

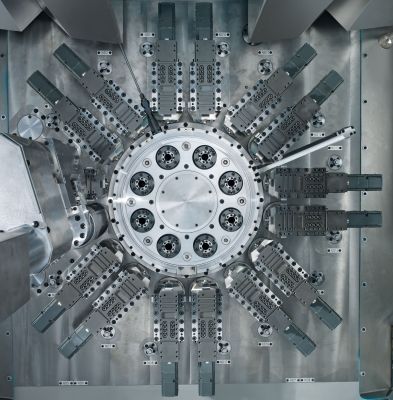

Each of the eight spindles, arranged in the Index spindle drum, are assigned two cross-slides which can travel both on the X as well as on the Z-axis. Each cross-slide can be additionally equipped with a Y-axis.

The speed of each of the eight liquid-cooled spindles can be controlled separately. The fluid-cooled spindle drum keeps the thermal growth in the spindle carrier to a minimum. The advantage compared to the previous air-cooling approach is the higher power density in the spindle drum and the capability of energy recovery from the heated cooling fluid. In addition, the spindle bearing temperature can be kept at a low level, which also prolongs its service life and improves thermal stability.