Polished Up!

Tool systems for grinding and honing today’s most challenging gears

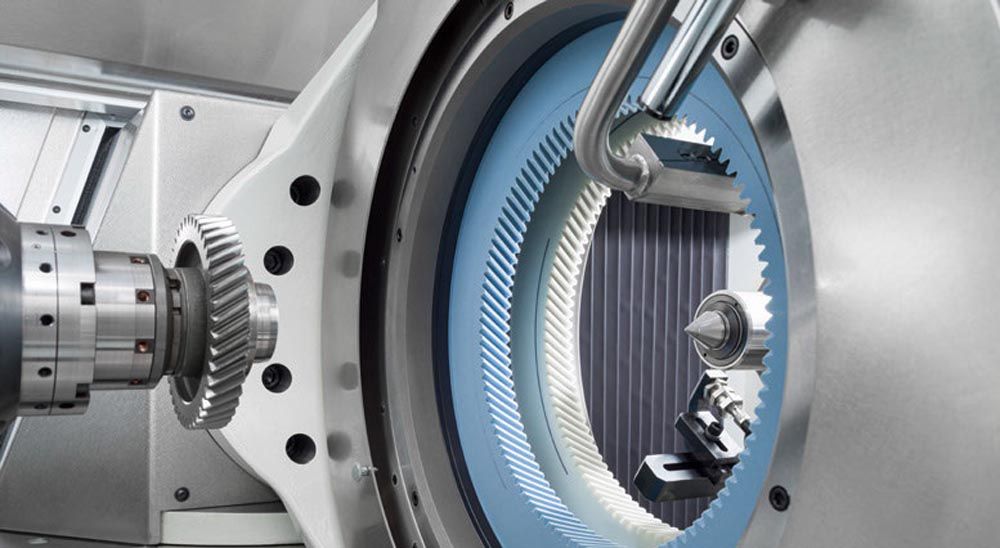

Gleason Combi Honing with two honing tools in one set-up, seen here as a polishing application.

Dr.-Ing. Nicolas Bleil, Gleason-Hurth Tooling GmbH

The trend towards hard fine finishing of gears for automotive transmissions is accelerating. In recent years, the focus has been on increasing the efficiency of gears in order to make optimum use of the narrow gear ratio range, gear by gear, and to reduce fuel consumption. Surface finish, in particular, is under increased scrutiny since it plays such a decisive role in achieving the noise and efficiency requirements of gear units for today’s EV applications.

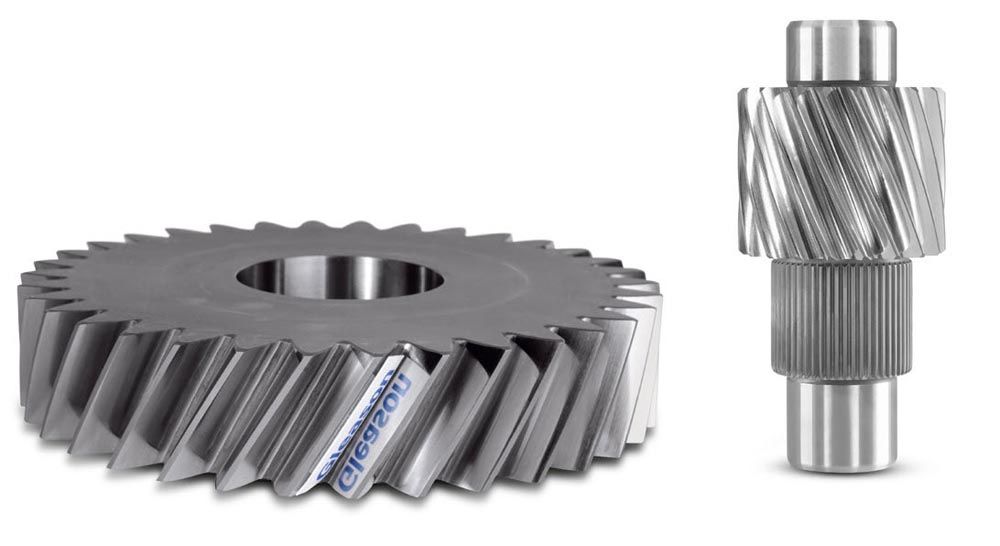

These higher gear quality standards are driving significant innovation in the grinding and honing manufacturing processes required to achieve them. Fine finishing and, in particular, polishing machining, offer a tailor-made approach to meet these objectives. Inherent in these processes is the fact that two machining steps (roughing and fine finishing) are performed sequentially, in a single setup. Alternatively, different processes can be combined to achieve the same end result, such as grinding with gear honing. The disadvantage of this approach, however, is that the workpiece must be loaded into a machine tool twice. What all these processes have in common is that they offer a wide range of tool specifications, including variations in grit size and bond type, to achieve the desired result in the finished workpiece.