State of the Gear Industry Perspectives: Kapp Technologies

State of the Gear Industry Perspectives takes an in-depth look at the challenges and opportunities in gear manufacturing today and in the future. Our sixth installment online is an interview with Shane Hollingsworth, vice president of sales, Kapp Technologies.

Shane Hollingsworth

Shane Hollingsworth

What are the greatest challenges to your business in 2023?

Coming into 2023 we are going to be quite busy with a number of new projects which is a good thing, but at the same time this brings on challenges that we have been facing the previous year that appear to not be going away. Supply chains are still stretched out and at times unpredictable which makes scheduling difficult, it’s no secret the industry is looking to solve a skilled labor shortage, mix in unreliable schedules only adding to the complexity. We are not seeing one area that is affected, it's everything from bearings, electronics, controllers, and vessel delays to name a few. One area we are continuously investing is the future planning of our workforce, we see that longer term investments are necessitated to build up the next generation employee where previously possible to employ someone with initial knowledge. Succession planning is becoming more and more important to avoid gaps in the future.

What global manufacturing trends are you paying close attention to in the gear industry today?

Clearly, the evolution of the EV market has significant attention. We have seen in Europe along with China that this market is further along being accepted. North America has only touched its toe in the water for this market, we see more and more projects being introduced, but still at a much lower production scale. Future energy prices, infrastructure, and legislation will be major influencers for how this market continues to develop.

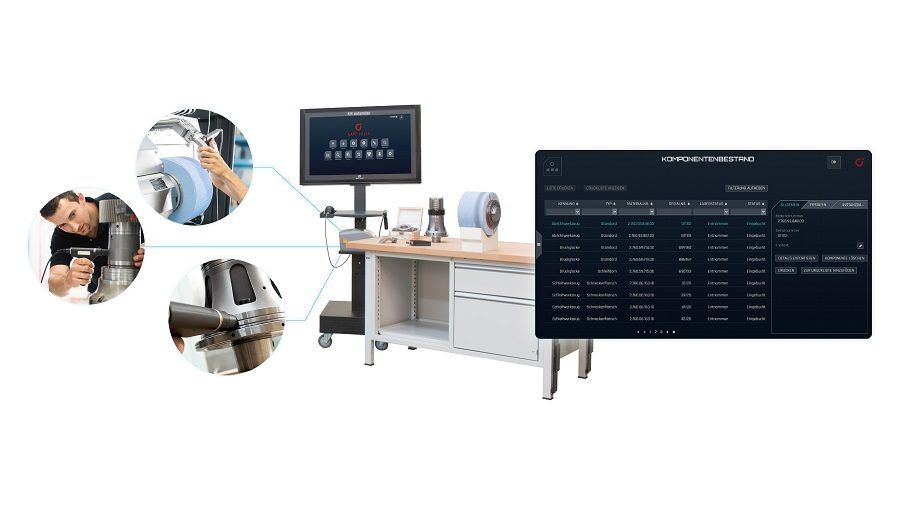

Skilled employees are one of the largest if not the biggest task we all face today, unfortunately this doesn’t appear to have a short-term solution and each organization is looking for a solution. States and local municipalities are making more and more investments which is a good start, but these need to grow on a larger scale to address the larger problem. The machines being built today are being tasked more to help alleviate this pressure, time will tell how far this evolves the controller's and software's of the future.