Figure 5 shows the stress components acting in a considered

element below the surface. In Figure 5a) the stress distribution

due to the normal force is shown, where the contact stress can

be described according to the Hertzian theory. The effects of the

relative sliding between the two gear flanks are considered with

the friction force. Figure 5b illustrates the bending stress distribution

over the tooth cross-section. Due to the normal force,

tensile stress is induced on the side of the loaded flank and compressive

stress on the back flank. In comparison to the bending

stress, which is nearly linear over the tooth cross-section, the

stresses due to shear load can be approximated by a parabolic distribution

with a maximum at the middle of the tooth. In Figure

5d the residual stresses are shown. As a result of the heat treatment,

compressive stresses normally occur in the case area, and

are compensated by tensile stresses in the tooth core. Unlike the

stresses in 5a, b and c, the residual stresses are load-independent

and constant over time if the load is not too high. The residual

stresses and the load induced stresses can be superimposed if the

different time dependence of the stress components is considered.

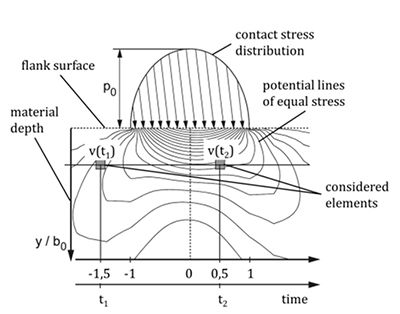

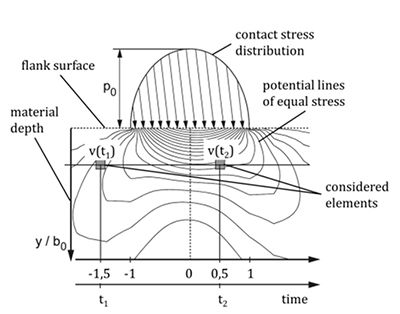

Figure 6 Time-dependent stress in the rolling contact (7).

Stress conditions in the rolling contact. On a loaded tooth

flank the rolling direction × can also be seen as the time axis. For

each considered element in the material the stress conditions

change due to the relative motion of the mating tooth flanks.

Figure 6 illustrates schematically the rolling contact with the

induced stress (one component of the 3-axis stress condition)

below the surface. Under the assumption of constant equivalent

radius of curvature and normal force, all volume elements

in the same material depth are exposed to equal stresses, but

at different times during the roll-over process. Furthermore, a

single volume element is subjected to different stresses at different

times, so when the material exposure is calculated in a

considered element below the surface, the stresses have to be

considered over the whole time axis (x-axis). However, the difficulty

in this observation is the turning of the principal coordinate

system during the rolling contact, resulting in a variation

of the absolute stress values as well as the direction of the principal

stresses for each volume element. The stress distribution

over the material depth is mainly influenced by the maximum

Hertzian pressure p0 resulting from the Hertzian contact load

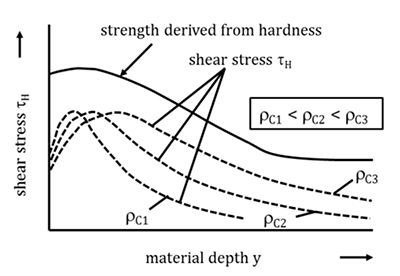

and the local equivalent radius of curvature ρc. As shown in

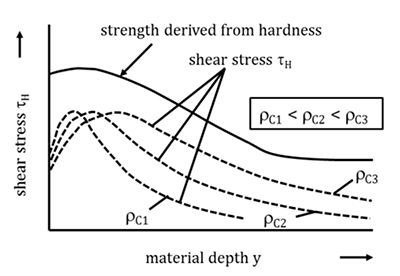

Figure 7, the shear stress τH below the surface increases with an

increasing equivalent radius of curvature ρc — even if the maximum

contact pressure p0 and maximum shear stress τH remain

the same. Because the relative radius of curvature increases

not only with increasing center distance, but also with increasing

pressure angle or increasing addendum modification factor,

an increased shear stress τH below the surface can be expected

in these gear configurations. Furthermore, based on the fact

that the local strength profile derived from the hardness profile

remains constant, the remaining strength reserve erodes and the

risk of a crack initiation below the surface increases.

Figure 7 Influence of the equivalent radius of curvature on the shear

stress below the surface (19).

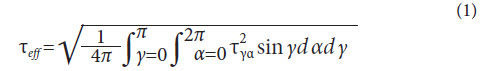

Multi-axial stress conditions are commonly described by

means of equivalent stresses. Theoretical investigations in

(Ref. 7) have shown that many of the common equivalent stress

hypotheses, such as the distortion energy hypothesis, shear

stress hypothesis and alternating shear stress hypothesis, are

not suitable for alternating stresses and stress conditions with a

rotating principal coordinate system. In (Ref. 7) various hypotheses

are discussed to their applicability for rating the material

exposure in rolling contacts. In (Ref. 7) it could be shown that

the so called shear stress intensity hypothesis (SIH) is applicable

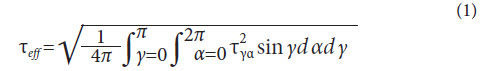

to loaded rolling contacts. The shear stress intensity τeff can be

calculated according to Equation 1; it considers all maximum

shear stresses τγα in each sectional plane γα of the considered

volume element.

Local material strength. Another decisive influence factor,

beside the stress conditions in the rolling contact, is the local

material strength limiting the load carrying capacity. Tooth

flank fracture can occur if the material strength below the surface

is exceeded. According to (Ref. 7) the material strength can

be determined based on material-physically relations where the

local strength values are calculated out of the local Vickers hardness.

An alternative, simpler method is used in (Refs. 6; 12–14;

16; 19) where the material strength is assumed to be directly

proportional to the local hardness. Further influences due to

grain size and segregation cannot be considered by the actual

state of the art.

Calculation Model

Basic formulae. A calculation model was developed at FZG to

determine the risk of tooth flank fracture. The model considers

different volume elements below the surface to determine

the local material exposure as a comparison of the local occurring

equivalent stress and the local strength that is derived from

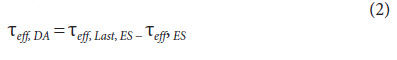

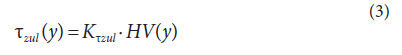

the hardness profile. Using Equation 2, the occurring local stress

based on the equivalent stress according to the shear stress

intensity hypothesis (SIH) can be calculated:

Both τeff, Last, ES and τeff, ES can be calculated using Equation 1.

However, different stress components are considered. For the calculation

of τeff, Last, ES all stress components due to external loads as

well as components due to residual stresses are used, whereas the

determination of τeff, ES is done only with the quasi-static residual stresses. Basically the decisive equivalent stress τeff, DA can be taken

as an oscillating stress with the double amplitude (Eq. 2). For the

calculation of the material exposure besides the occurring local

stress, the local strength derived from the hardness profile below

the surface is required:

Although there is no generally valid relation between the permissible

shear strength and the local hardness, simplified it can

be assumed that the material strength, especially on case-hardened

gears, is directly proportional to the local hardness. The

factor describing the linear relation between the Vickers hardness

and material strength has a constant value of 0.4, which

was derived from gear running tests and results from industry

gearboxes. This value is valid for case-carburized gears made

of typical case-hardening steels and with adequate heat treatment.

With τeff, DA and τzul the material exposure AFB for each volume

element below the surface can be determined according to

(Ref. 19) using Equation 4:

With the calculation of the material exposure AFB over the

material depth at different points from the tooth root towards

the tooth tip the risk of tooth flank fracture can be evaluated for

different mesh positions considering the local equivalent radius

of curvature, the local contact pressure and the local hardness.

The limit for the material exposure AFB, above which tooth flank

fracture should be expected, was set to 0.8. This critical value

was derived from gear running tests on test gears and recalculation

of gearboxes from different industry applications.

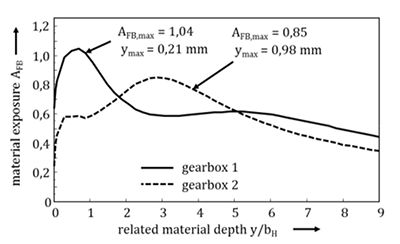

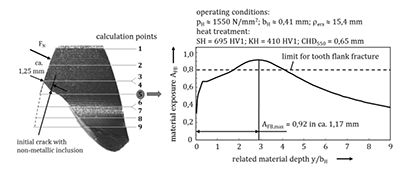

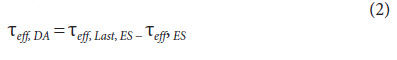

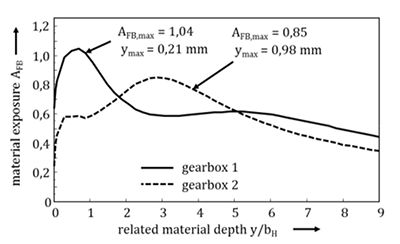

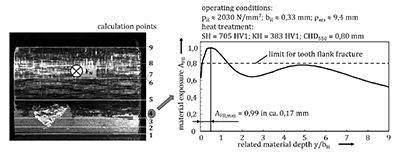

Figure 8 Comparison of the calculated material exposure curves for two

example gearboxes (19).

Figure 8 shows the comparison of two calculated material

exposure curves for two example gearboxes. The material exposure

maximum AFB, max for gearbox 1 is reached near the surface,

whereas the maximum exposure AFB, max for gearbox 2 can be

observed in greater material depth. The location of the peak is

mainly influenced by the equivalent radius of curvature, by the

occurring contact loads and by the heat treatment parameters.

Depending on the location of the maximum material exposure,

the failure type can be predicted. High material exposure values

at the surface indicate pitting whereas material exposure peaks

in greater depth can be interpreted as at high risk of tooth flank

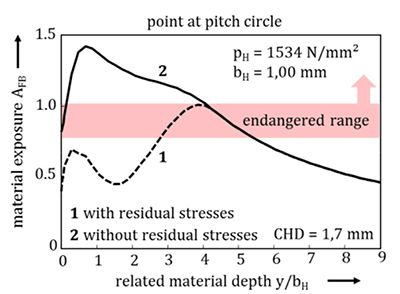

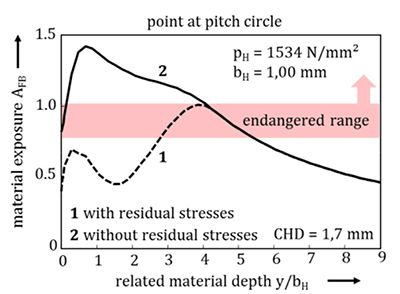

fracture. Figure 9 shows a variation calculation of the material

exposure for one contact point with and without consideration

of the compressive residual stresses near the surface. By neglecting

the compressive residual stresses in the case their positive

effect on the material exposure is lost, which always leads to a

maximal exposure close to the surface. By using the reduced calculation

model without consideration of the residual stresses the

tooth flank fracture failure, which has its initial crack in greater

material depth, cannot be reproduced. This indicates a decisive

influence of the residual stresses on the calculation results. Thus

fatigue failures due to tooth flank fracture can only be evaluated

correctly if the residual stresses are considered during the calculation.

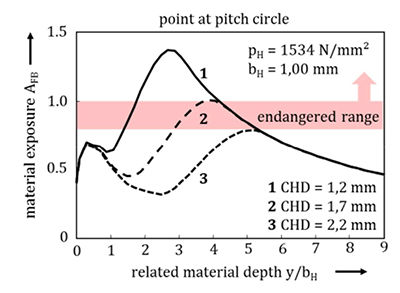

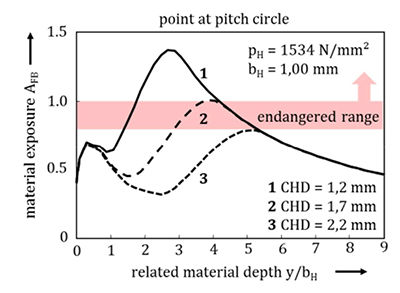

As shown in Figure 10 the reduction of the case-hardening

depth (curve 1) leads to an increase of the maximum material

exposure in greater material depth, whereas the local maximum

near the surface remains almost unchanged. Furthermore the maximum of the material exposure shifts towards

the surface. Because of the reduced CHD, the core

hardness is already achieved in smaller material depth

while the hardness near the surface remains the same.

An increase of the CHD has the effect that the maximum

value of the material exposure is decreased and

shifted towards greater depth. All three curves indicate

a strong influence of the case hardening depth

on the maximum material exposure and its location

below the surface. The local peak near the surface is

not significantly changed by the CHD variation.

Figure 9 Material exposure curve for one contact point calculated with

and without residual stresses (19).

Figure 10 Influence of the CHD on the calculated material exposure (19).

The presented calculation model has the following

features and capabilities:

- Check if the maximum material exposure occurs

near the surface of the loaded flank or in greater

material depth;

- Check if the maximum material exposure is exceeded;

- Predict how deep below the surface an initial crack

may occur and consequently which type of failure

can be expected;

- Evaluate the risk of tooth flank fracture;

The most decisive influence factors that can be

optimized in order to reduce the risk of tooth flank

fracture are the gear geometry, represented by the

local equivalent radius of curvature, the gear external

loads, and the heat treatment.

Validation of the calculation model with test

results. A number of tests with test gears especially

designed to fail due to tooth flank fracture were carried

out in order to prove the applicability of the calculation

model, and to verify the critical value of 0.8

of the material exposure. On these test gears the failure

of tooth flank fracture was dominant, as it could

be reproduced repeatedly during the tests. All failed

gears had a maximum material exposure in material

depth which was higher than the limit of 0.8.

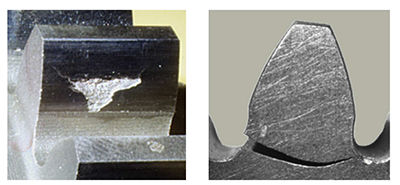

Examinations of the fracture area showed that in

almost all cases the initial crack occurred in the casecore

transition at non-metallic inclusions, such as

aluminum-oxides and/or manganese-sulfides, in an

approximate material depth between 0.8 and 1.9 mm.

Hereby, the different operating conditions and case-hardening

depths of the test gears have to be considered.

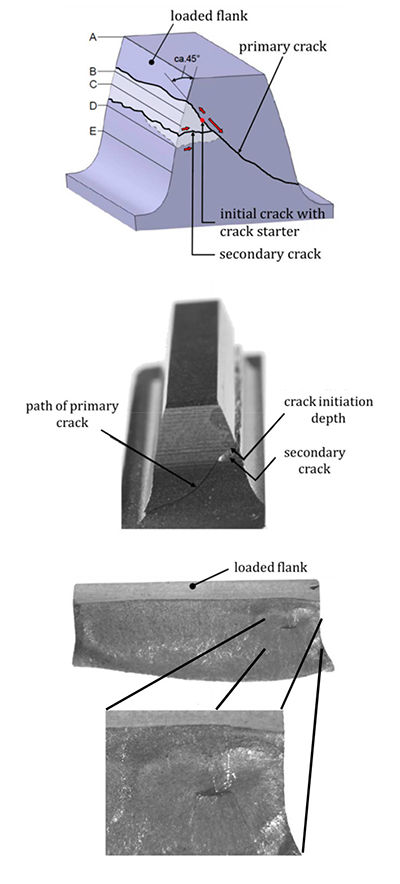

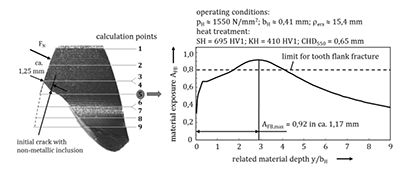

Figure 11 shows example comparison between test result

from the gear running tests and the corresponding calculated

material exposure. Because of characteristic features, the failure

could be identified as tooth flank fracture (Fig. 11, left). The initial

crack occurred at flank mid-height in a depth of ca. 1.25 mm

below the loaded flank surface, which equals nearly twice the

case hardening depth. In Figure 11, right, the calculated material

exposure curve for mesh position 5 is plotted over the material

depth. The maximum value of AFB, max = 0.92 occurring in a

depth of 1.17 mm exceeds the limit of 0.8 and therefore indicates

a significant risk of tooth flank fracture. The critical material

depth derived from the gear test was very well represented by

the calculation as well.

Figure 11 Comparison of test result and calculated material exposure (example for

tooth flank fracture).

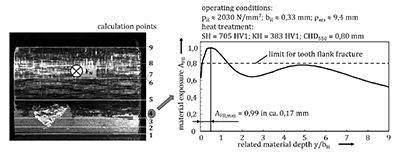

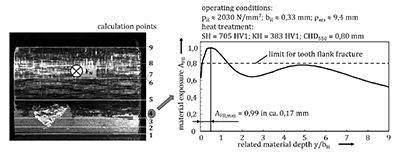

For comparison, a test gear used for pitting investigations

(mn = 5 mm, a = 91.5 mm, z1.2 = 17/18) is shown in Figure 12.

The pitting failure, as illustrated on the left, occurred during the

test run near the tooth root at mesh position 4. The maximum

material exposure of AFB, max = 0.99 in this position is found just

below the loaded flank surface, while the material exposure in

greater material depth is slightly below the limit for tooth flank

fracture of 0.8 and therefore still non-critical regarding tooth

flank fracture. Consequently a good correlation between the test

and the calculation results is present.

Figure 12 Comparison of test result and calculated material exposure (example for

pitting)..

Figure 13 summarizes the results from calculation studies

regarding tooth flank fracture, including gearboxes from different

applications such as wind turbines, water turbines, highspeed

gearboxes and roller mills. For all examined gearboxes

the calculated global maximal material exposure is given. The

gearboxes on the left failed due to tooth flank fracture and for

all gearboxes on the right side no damage or failures due to flank breakage were reported. A good correlation can be found

between the calculated maximum material exposures and the

observations of the different industrial gearboxes. The comparison

confirms tooth flank fracture failures when the critical value

of 0.8 of the material exposure is exceeded. All other gearboxes,

where no flank breakage occurred, lie beneath 0.8. In general a

good applicability of the calculation method could be observed.

Figure 13 Calculated maximum material exposure for different industrial

applications (19).

Conclusions

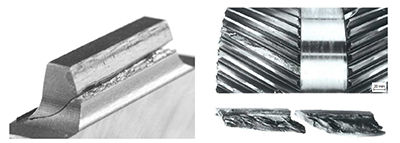

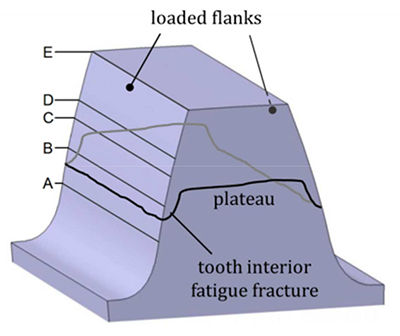

Tooth flank fracture is a sub-surface fatigue failure mode

observed on case hardened gears. One characteristic feature of

tooth flank fracture is that in comparison to pitting and tooth

root breakage, the initial crack can be found below the loaded

surface, in greater material depth. Tooth flank fracture leads

in almost all cases to the complete breakdown of the gear set.

Due to the fact that the crack is propagating inside the material,

the failure occurs spontaneously and often without any indications.

Standardized calculation methods for pitting and tooth

root breakage according to ISO 6336 do not cover this kind of

failure. Because of the different failure mechanism, systematic

investigations and the development of a new calculation method

were of a great importance. The risk of tooth flank fracture

can be described with the so called material exposure, which

is defined as a relation of the local equivalent shear stress and

the local material strength in each volume element in material

depth. One distinctive feature of tooth flank fracture is that

the crack initiation is normally located below the flank surface

in an approximate depth of the case-core transition due

to high material exposure — mostly at stress risers like nonmetallic

inclusions. With time the initiated crack propagates

bi-directionally towards the loaded flank and the tooth fillet of

the unloaded flank. When the primary crack reaches the surface,

the upper tooth part is separated within a short time due

to overload breakage. Both the crack propagation and the overload

breakage can be observed on the fracture area — typical for

tooth flank fracture. Extensive experimental investigations have

shown that the gear geometry, operating conditions, gear material

and heat treatment are the decisive factors that influence

the risk of tooth flank fracture. A new calculation method was

developed in order to calculate the material exposure below the

flank surface. It enables the evaluation of the risk of tooth flank

fracture and the optimization of the gear design considering all

important influence parameters. The validation of the new calculation

method shows good correlation with the results from

gear running tests and from industrial gear boxes. Because of

the fact that tooth flank fracture is a sub-surface fatigue failure

that can occur in any application of highly loaded case-hardened

gears, the risk should always be considered during the

gear design. The new calculation model based on the material

exposure below the surface enables the prediction of tooth flank

fracture and the optimization of the geometry, material and heat

treatment so the risk of a failure can be reduced significantly.

Although the newly developed calculation method is based on

simplified approaches and assumptions, it allows the evaluation

of the tooth flank fracture risk and stays in good correlation

with experiences from the field. Goals of future studies are the

investigation of further influence factors and their numerical

quantification.

References

- Bauer, E. “Beispiele für Verzahnungsschäden, Ausgehend von

Innenliegenden Fehlstellen,” Allianz Report 68, Heft 6, 1995, S. 230–238.

2. Bauer, E. “Flankenbrüche bei Hochleistungsgetrieben,” Allianz Report 2,

1998, S. 79-87.

- Bretl, N., T. Tobie and P. Oster. “Load Carrying Capacity of Nitrided

Gears: Mechanical Properties, Main Influencing Factors and Critical

Evaluation of the Application in Gear Transmissions,” Tagung Nitrieren und

Nitrocarburieren, Aachen, 2010.

- (4) DIN 3990: Teil 1-5, Berlin, Beuth Verlag, 1987, Tragfähigkeitsberechnung

von Stirnrädern.

- (5) DNV: Tooth Interior Fatigue Fracture for Case Hardened Gear Wheels &

Pinion, Technical Information Newsletter No. 01/2009.

6. (6) Elkholy, A. “Case Depth Requirements in Carburized Gears,” Wear 88,

1983.

- (7) Hertter, T. “Rechnerischer Festigkeitsnachweis der

Ermüdungstragfähigkeit Vergüteter und Einsatzgehärteter Zahnräder,”

Dissertation TU München, 2003.

- (8) ISO 6336: Calculation of Load Capacity of Spur and Helical Gears, Teil

1-5, Genf, 2003.

- (9) Lang, O.R. “Berechnung und Auslegung induktiv gehärteter Bauteile,”

Berichtsband zur AWT-Tagung, Induktives Randschichthärten, Darmstadt,

1989.

- Mack Aldener, M. “Tooth Interior Fatigue Fracture and Robustness of

Gears,” Dissertation KTH Stockholm, 2001.

- Oster, P. “Beanspruchung der Zahnflanken unter Bedingungen der

Elastohydrodynamik,” Dissertation, TU München, 1982.

- Pederson, R. and R.L. Rice. “Case Crushing of Carburized and Hardened

Gears,” Trans. SAE, 1961.

- Sandberg, E. “A Calcualtion Method for Sub-Surface Fatigue,” International

Symposium on Gearing and Power Transmissions, Tokyo, Volume 1, 1981.

- Sharma, V.K., D.H. Breen and G.H. Walter. “An Analytical Approach for

Establishing Case Depth Requirements in Carburized and Hardened Gears,”

Trans. of ASME, DETC, Chicago, 1977.

- Tobie, T., B.-R. Höhn and K. Stahl. “Tooth Flank Breakage — Influences on

Subsurface Initiated Fatigue Failures of Case Hardened Gears,” Proceedings of

the ASME 2013 International Design Engineering Technical Conferences and

Computers and Information in Engineering Conference, Oregon, 2013.

- Tobie, T. Zur Grübchen- und Zahnfußtragfähigkeit Einsatzgehärteter

Zahnräder, Einflüsse aus Einsatzhärtungstiefe, Wärmebehandlung und

Fertigung bei unterschiedlicher Baugröße, Dissertation, TU München, 2001.

- Wirth, C., B.-R. Höhn and C. Braykoff. “New Methods for the Calculation

of the Load Capacity of Bevel and Hypoid Gears,” AGMA Technical Paper

12FTM15, 2012.

- Witzig, J. Entwicklung eines erweiterten Berechnungsverfahrens zur

Ermittlung optimaler Zahnflankentragfähigkeit bis in den Bereich

großer Werkstofftiefen, FVA Forschungsheft Nr. 1000, Frankfurt a. M.:

Forschungsvereinigung Antriebstechnik e.V., 2011.

- Witzig, J. “Flankenbruch. Eine Grenze der Zahnradtragfähigkeit in der

Werkstofftiefe,” Dissertation TU München, 2012.