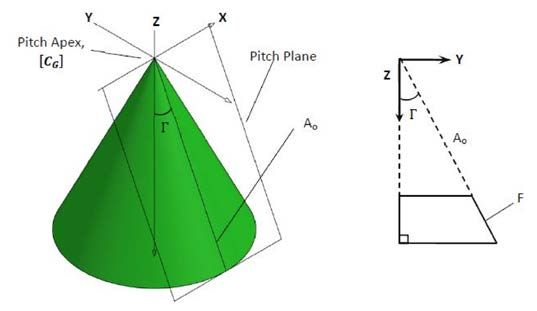

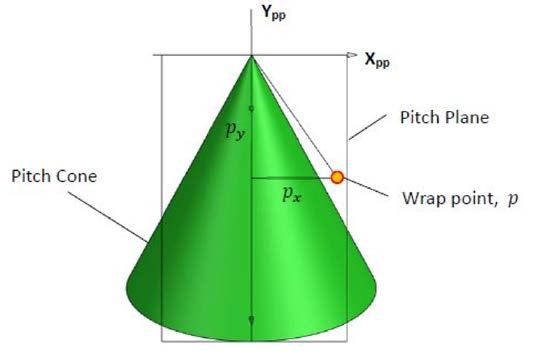

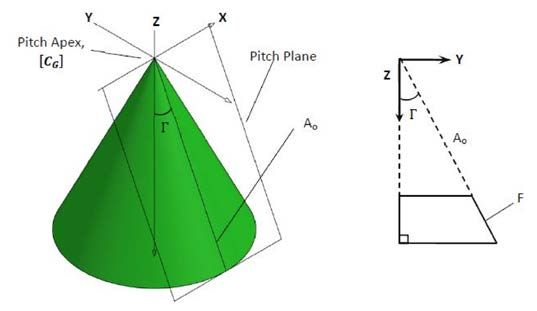

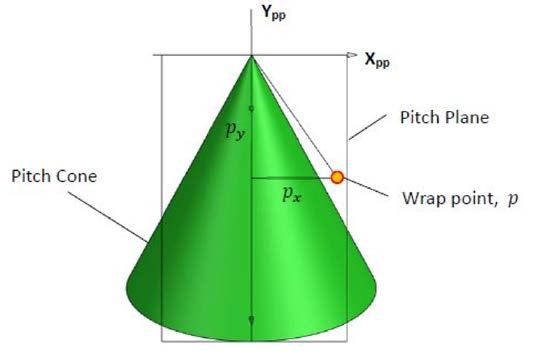

All bevel gears are designed using a reference right cone called

the “pitch cone.” The pitch cone is used as a basis for describing

all other geometric entities of the bevel gear. Since describing

the motions of the generating process in three dimensions

would be hard to visualize or comprehend, the general practice

is to un-wrap the surface of the pitch cone into a tangent

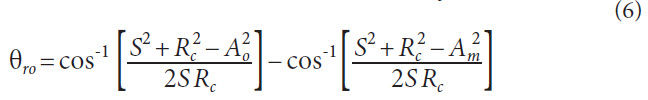

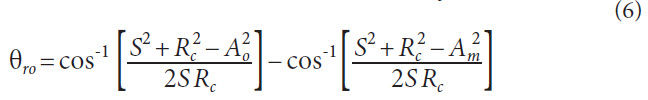

plane — or “pitch plane.”

The point at the top of the pitch cone is called the “pitch

apex.” The pitch apex is significant because the axes of both gear

and pinion intersect at this point. Figure 2 displays the pitch

cone, the pitch plane unwrapped, and also describes the global

Cartesian coordinate system, CG. Figure 2 also shows the pitch

cone sectioned through the YZ plane. This describes the definition

of the pitch angle, Γ, and the face width, F — of a part. The

global coordinate system follows the right-hand rule and its origin

is located at the pitch apex of the member being modeled.

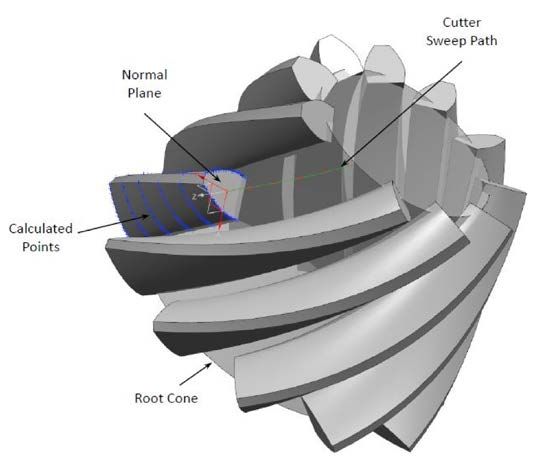

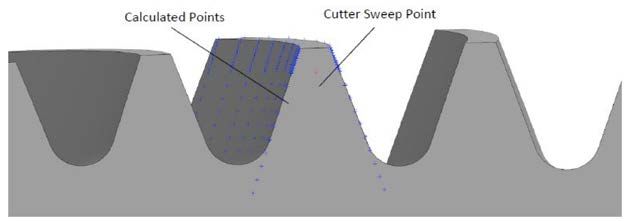

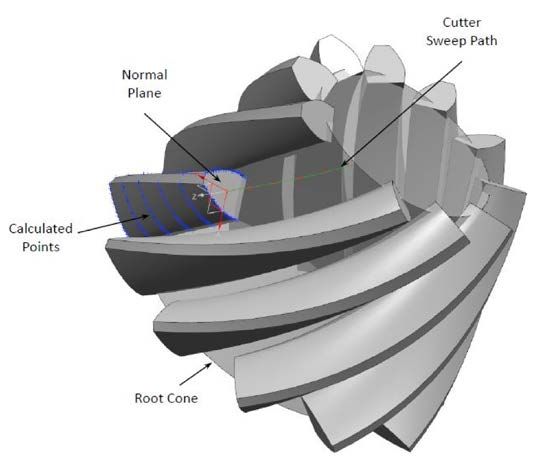

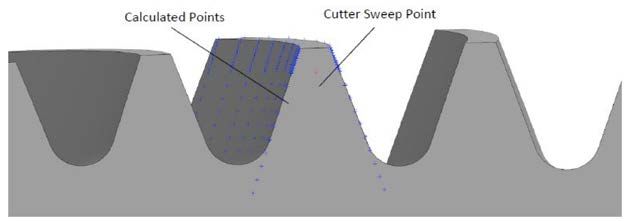

Figure 1 Visual depiction of calculation method.

Figure 2 Pitch cone.

Basic Generation

The majority of all generated spiral bevel gears are manufactured

in one of two processes, i.e. — face milling or face hobbing;

both manufacturing methods have advantages and disadvantages.

For the purposes of this method, a brief understanding

of the generating method utilized during these processes is

necessary to realize the 3D model.

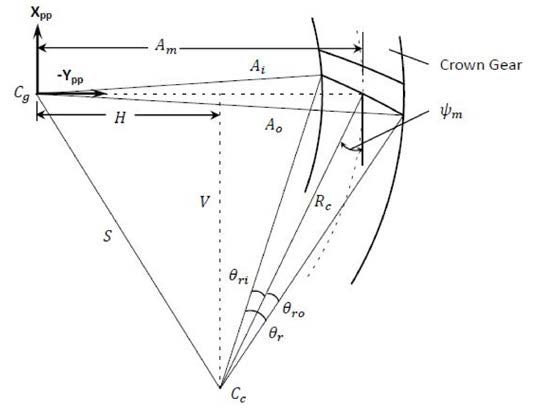

Face milling. The face milling manufacturing method

employs a circular, cup-shaped cutting tool moving in a timed

relationship with the workpiece to roll through the gear blank

and generate an individual slot. The cutter is then withdrawn, the work is indexed to the location of the next slot, and the process

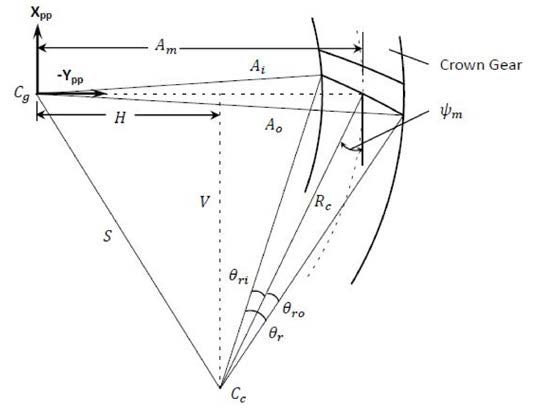

repeated. See Figure 3.

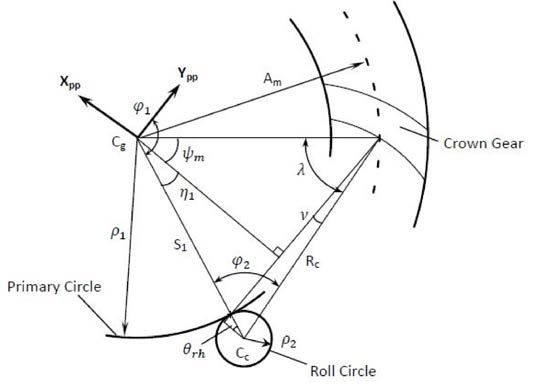

Figure 3 Generating triangle in pitch plane for face milling.

Figure 3 displays three instances of the cutter as it passes

through the workpiece; these points are at the toe, mean, and

heel of the crown gear. The path of the cutter sweeps a circular

arc in the lengthwise direction, with the same radius as the

radius of the cutter, Rc. The axis of the crown gear, Cg, is known

as the machine center. The local coordinate system for the pitch

plane is located at the machine center. Xpp correlates to X and

Ypp lies along the line describing Ao in Figure 2.

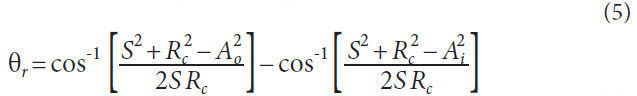

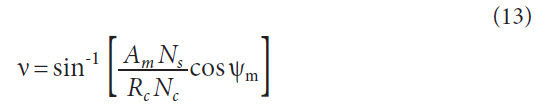

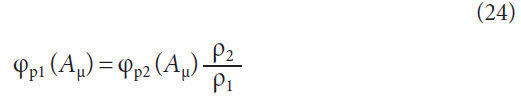

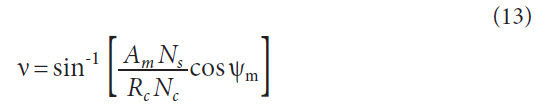

The cutter axis, Cc. This location can be found by:

The sign of the vertical term, V, may either be positive or negative,

depending on the hand of spiral to be modeled. Figure 3

shows a right-hand member (use negative value for V when calculating

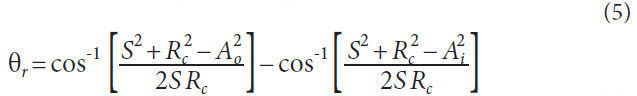

left-hand members). The cutter sweep angle, θr, is necessary

to determine how much rotation is used during the cutting

process. When calculating points to model the gear tooth,

these will be the endpoints of the working portion of the cutter

path.

Discrete points can be calculated along the cutter sweep on

the pitch plane. Using the general parametric formulas for a circle,

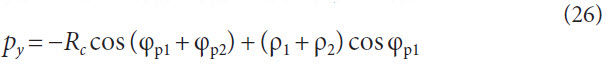

the solution for a point, p, along the cutter path is:

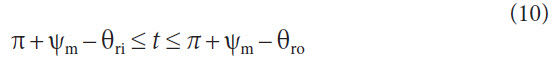

Where t is a parameter that has the following ranges:

For left-hand members,

For right-hand members,

This cutter path can be broken into as many discrete sections

as desired.

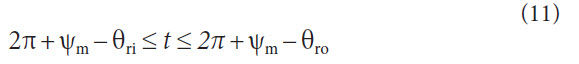

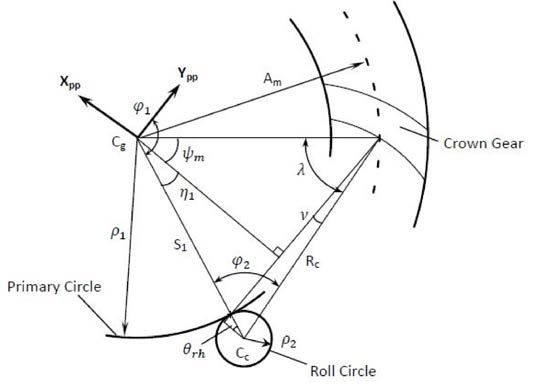

Face hobbing. The face hobbing manufacturing method is

a continuously indexing process. The cutting tool has groups

of staggered blades; the workpiece moves in a timed relationship

with the cutter so that a group of blades in the cutter passes

through a slot of the workpiece. The face hobbing method generates

an extended epicycloidal shape in the lengthwise direction.

See Figure 4. for a detailed layout of the face hobbing generating

triangle.

Figure 4 Generating triangle in pitch plane for face hobbing.

Since the lengthwise shape of a face hobbed part creates an

extended, epicycloidal shape, a little trigonometry is necessary

to calculate the discrete points along the path created by the cutter.

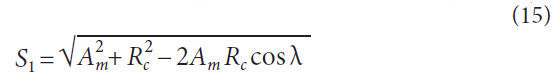

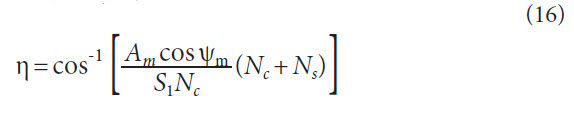

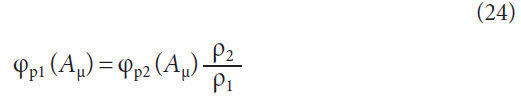

The crown gear tooth count,

The lead angle of the cutter,

The first auxiliary angle,

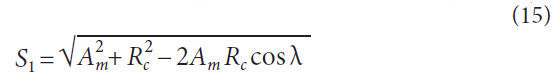

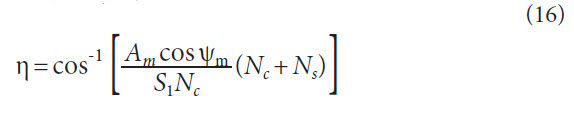

The center distance from crown gear center to cutter (Radial),

The second auxiliary angle,

The second roll angle,

The auxiliary roll angle,

The radius of the roll circle,

The radius of the primary circle,

The first roll angle (assuming rolling without sliding),

Now that the dimensions of the cutting cycle’s epicycloid,

the cutter path, can be calculated, it would be very difficult to

determine the angle of sweep that the cutter makes during the

generating process because the cutter axis does not remain stationary

during the cutting cycle. The face width of the bevel gear

being modeled will be subdivided into discrete portions; the roll

angles need to be recalculated for each discrete location individually.

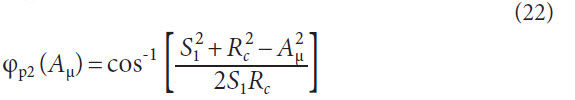

The second roll angle as a function of cone distance,

Where,

The first roll angle as a function of cone distance,

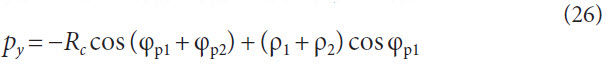

The local Cartesian coordinates describing a point, p, along

the cutter sweep path can be calculated.

Wrapping the Pitch Plane

The pitch plane is a tangent plane to the lateral surface of a right

cone. This cone, as described earlier, is the “pitch cone.” The

diagrams take into account the set-up of the machine, the cutter

size, and the motion of the cutter. Rotation of the workpiece

also needs to be accounted for; this is accomplished by wrapping

the pitch plane around the pitch cone. This transforms the

local coordinates calculated for the cutter sweep path into global

coordinates. These points in the global coordinates will define

the center of a tooth slot. The following formulas will transform

a point, p, from the local XppYpp plane to the global Cartesian

coordinate system, CG.

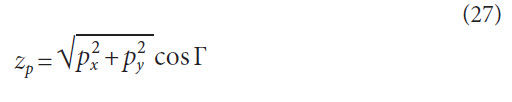

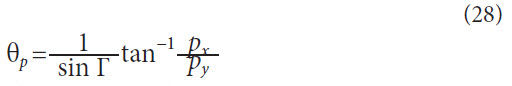

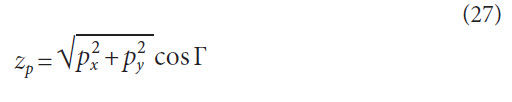

The first step is to determine the location of the point in the

global Z axis direction,

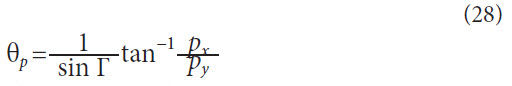

Calculate the rotation angle that the point will wrap around

the cone,

Calculate the radius of the cone at location, Zp,

Convert the cylindrical coordinates for the wrap point into

global Cartesian coordinates.

Therefore, all the local cutter positions can be wrapped and

transformed into the global Cartesian coordinate system.

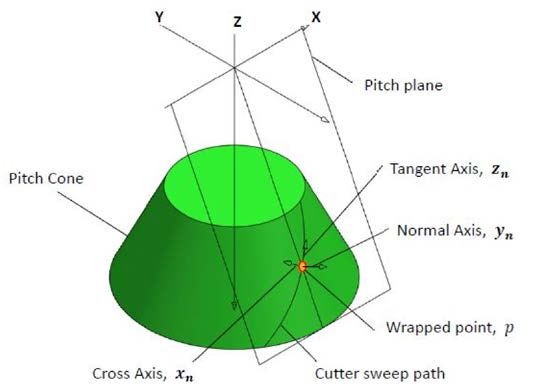

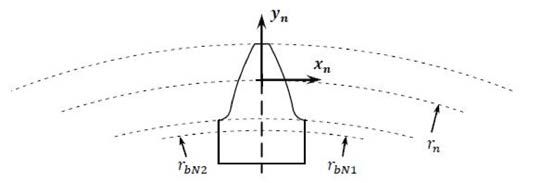

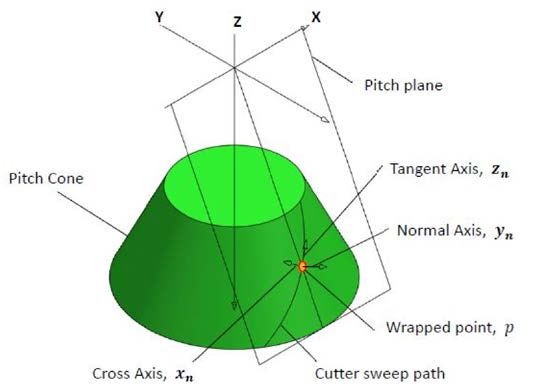

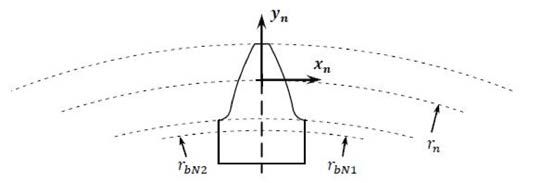

Calculating Local Cutter Coordinate System

Since AGMA 929 effectively calculates the normal circular tooth

thicknesses at a specific spot along the cutter path, the next step

is to determine the correct orientation of the normal plane. A

complete coordinate system will be oriented to have the xnyn

plane normal to the cutter path, with the origin at each global

coordinate of the cutter path calculated previously; this coordinate

system will be called Cn.

Tangent axis, zn. The tangent axis is defined by a vector that is

tangent to the cutter sweep path at the location of the wrapped

point. There are a couple of options for calculating this tangent

vector. One could calculate the first derivative of the cutter

sweep path formulas for both face milling and face hobbing

so that the slope anywhere along that path can be predicted.

Once that is accomplished a vector can be constructed in three

dimensions to describe this tangent axis.

Since many assumptions are made throughout this method,

the simplest method for calculating an approximate tangent

vector is using finite difference; the finite difference method is

described in the following equation:

It is difficult to determine the correct size of Δx that will

approximate the tangent close enough for this method. Since

the cutter sweep path is smooth and continuous for all locations along the arc, it is possible to quantify the error of our approximation

using a Taylor expansion. This is beyond the scope of

this document, but is mentioned here for further exploration.

The practical approach to applying the finite difference method

is to calculate a neighboring wrapped point along the cutter

sweep path for each wrapped calculation point. A vector can

then be defined by passing through both sweep path points. As

the points become closer and closer the vector connecting the

two points approaches a tangent line.

Figure 4 Generating triangle in pitch plane for face hobbing.

Figure 4 Generating triangle in pitch plane for face hobbing.

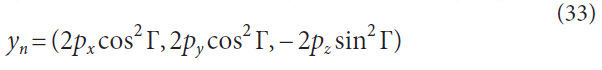

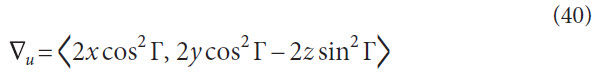

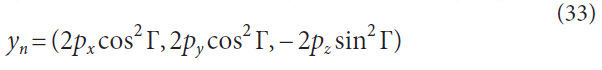

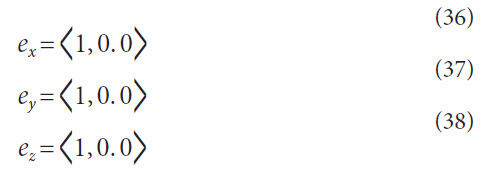

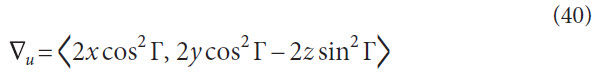

Normal axis — yn. The normal vector is defined as a vector

radiating perpendicularly from the surface of the right cone at

the wrapped point location (Fig. 6). The normal vector at wrap

point p = (px, py, pz) can be calculated by the following equation:

A brief derivation will follow to explain the calculation of the

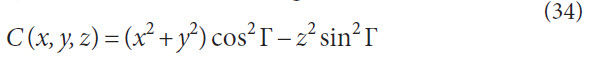

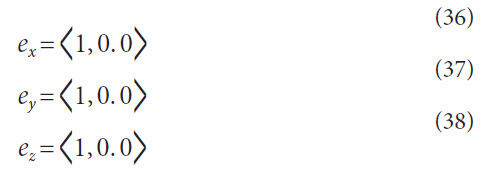

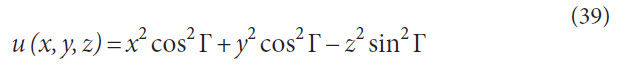

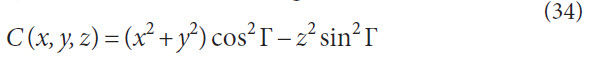

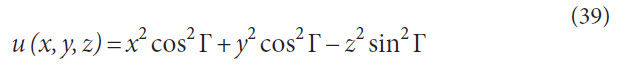

normal axis. The general function of a right cone,

A gradient, u, is always normal to a function when,

Where,

Let,

Therefore,

The cross vector will complete the definition of the local

Cartesian coordinate system. This vector is calculated by taking

the cross product of the tangent vector and the normal vector.

After calculating all the vector directions for the local coordinate

system, all three of the vectors should be normalized.

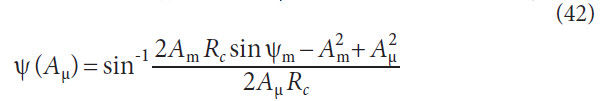

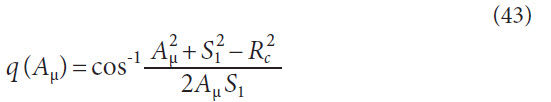

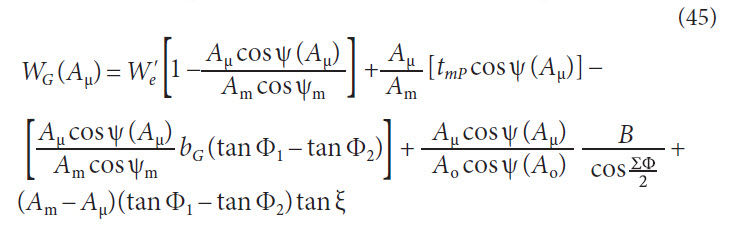

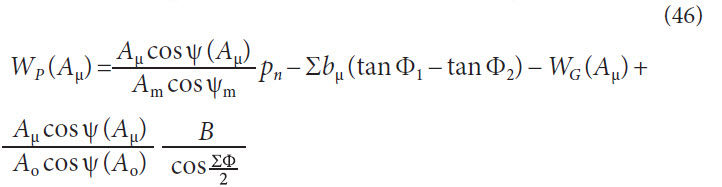

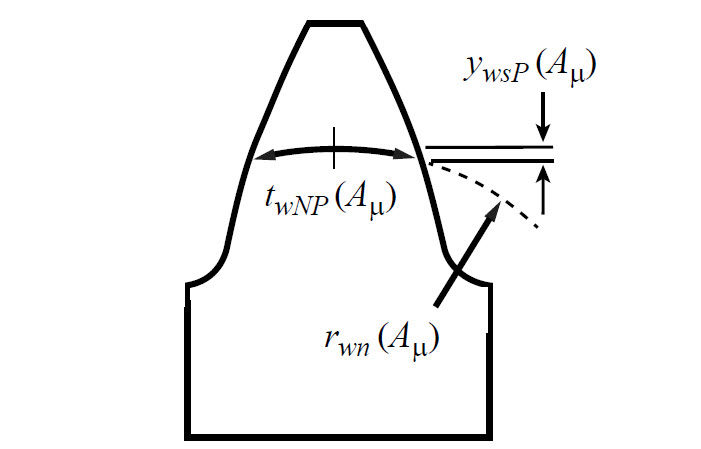

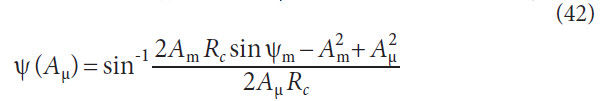

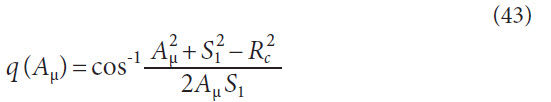

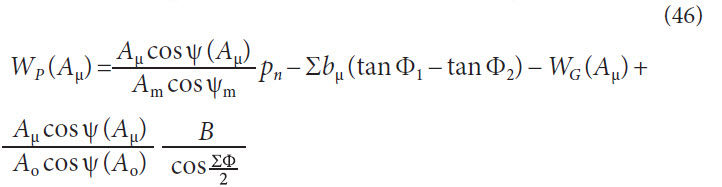

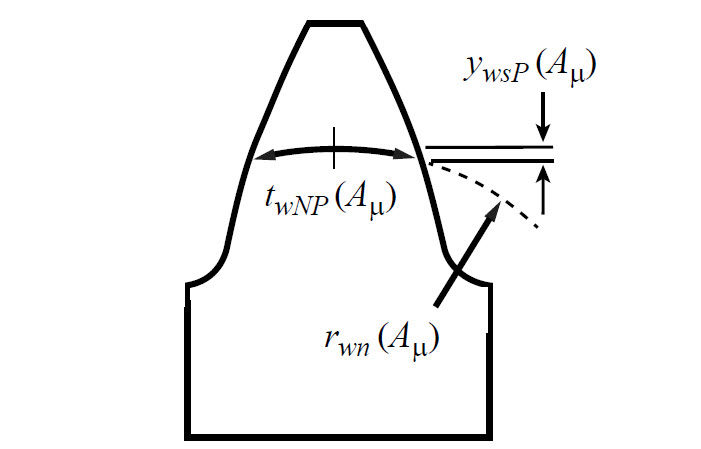

Normal Circular Tooth Thickness Calculations

Generalizing AGMA 929-A06. As previously discussed AGMA

929-A06 utilizes the technique of converting the spiral bevel

gear tooth to a virtual spur gear tooth to calculate the top lands

at the toe, mean, and heel; the equations presented in AGMA

929-A06 are unique for each of these points of interest. General

equations can be derived from AGMA 929-A06 so that the

tooth thickness can be calculated anywhere along the profile

and lengthwise direction. The generalized formulas for the conversion

to a virtual spur gear are presented here (Fig. 7).

Figure 7 Definition of the geometry of the virtual spur gear in the

normal plane.

Also,

a handful of helpful formulas for calculating some spiral gear

tooth geometry with respect to cone distance,

Aμ, are developed.

The cone distance range variable must correlate to the cone distances

first chosen in the cutter path sections.

The notation in this section utilizes the terminology as if the

member being modeled is the gear. Unless specifically specified

the gear terminology should be replaced with pinion terminology

in the formulas if the pinion is the part being modeled.

Spiral angle for face milling with respect to cone distance,

Generating angle for face hobbing with respect to cone distance,

Spiral angle for face hobbing with respect to cone distance

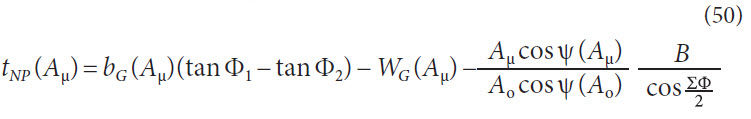

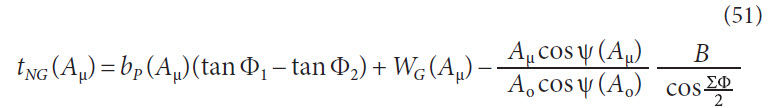

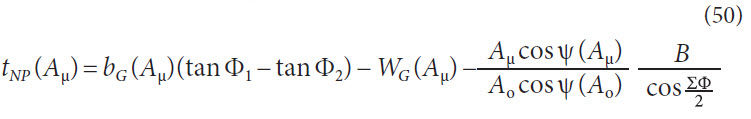

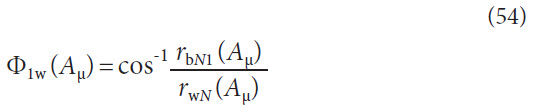

Slot width with respect to cone distance for the gear member,

Slot width with respect to cone distance for the pinion member,

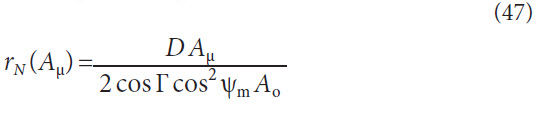

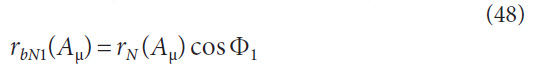

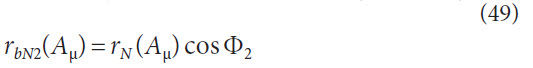

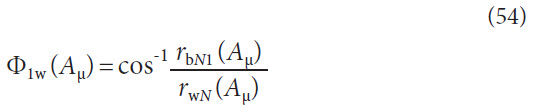

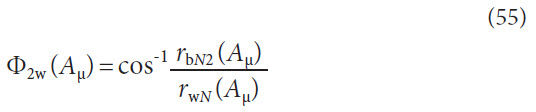

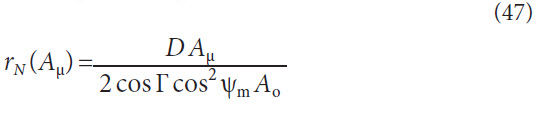

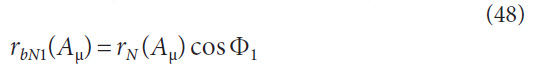

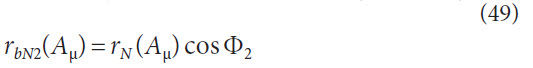

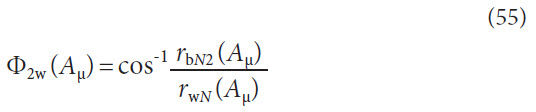

Normal pitch radius with respect to cone distance (substitute

proper pitch diameter and pitch angle for member to model),

Normal base radius with respect to cone distance, concave,

Normal base radius with respect to cone distance, convex,

Figure 7 displays the base radii graphically. The value of rrbN1

and rbN2 are shown as the same value because the pressure angle

of the concave and convex flanks are the same. This is typical

but not mandatory for bevel gears without a hypoid offset.

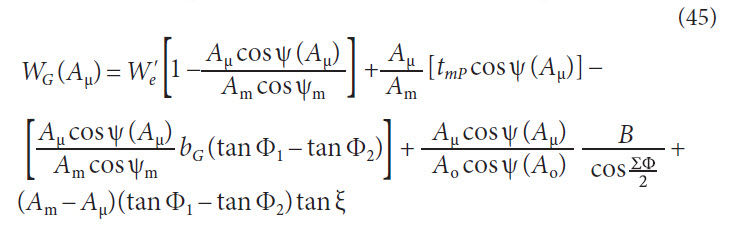

Normal pinion circular tooth thickness at pitch line with

respect to cone distance,

Normal gear circular tooth thickness at pitch line with respect

to cone distance,

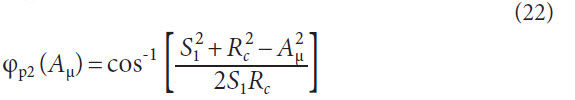

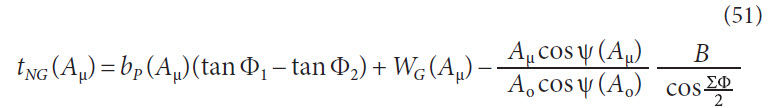

Normal working radius with respect to cone distance,

Where

w is a range variable for calculating the working radius. The

valid range for w is,

Pressure angle at working radius with respect to cone distance,

concave,

Pressure angle at working radius with respect to cone distance,

convex,

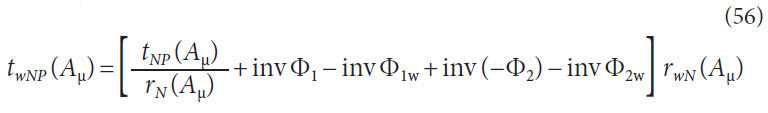

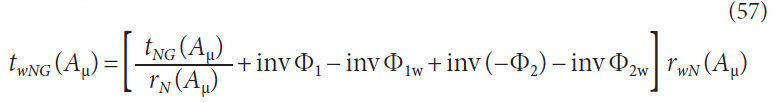

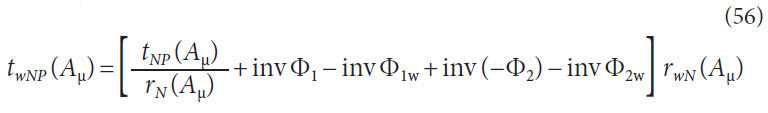

Normal circular tooth thickness for pinion at working radius

with respect to cone distance,

Normal circular tooth thickness for gear at working radius

with respect to cone distance,

Certain designs have the dedendum plunge below the virtual

gear’s base radius; when this occurs, the normal circular tooth

thickness will become a complex number. Only the real portion

of this value should be used when recording the answers.

Converting thicknesses to coordinates. The tooth thickness

calculations shown earlier in Generalizing AGMA 929-A06 is a

circular tooth thickness positioned at a specified working radius.

The local coordinate system has the origin located where the

pitch radius crosses the center of the tooth thickness (Fig. 7). For

each working radius used the calculated circular tooth thicknesses

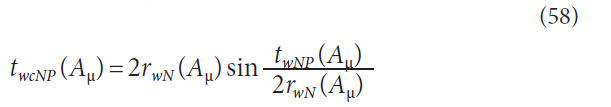

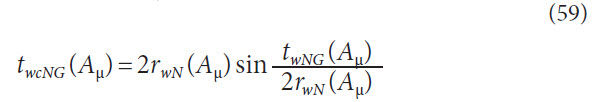

need to be converted to chordal thicknesses before they

can be recorded as Cartesian coordinates.

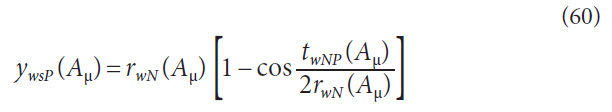

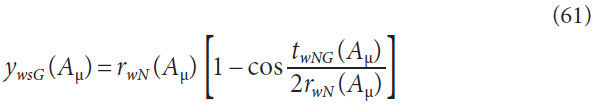

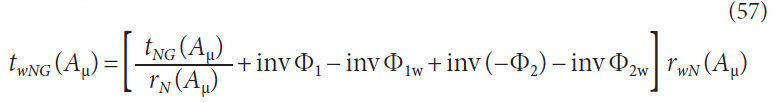

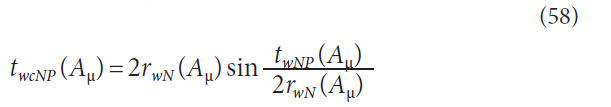

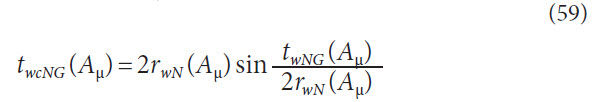

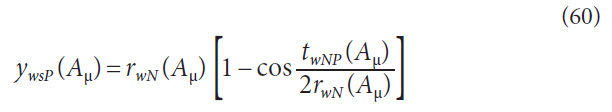

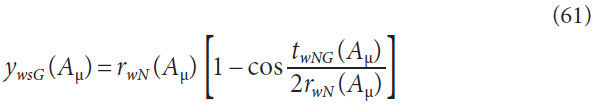

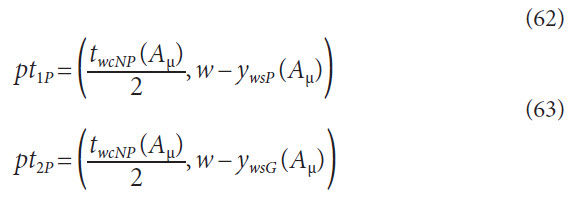

Normal chordal tooth thickness for pinion at working radius

with respect to cone distance,

Normal chordal tooth thickness for gear at working radius

with respect to cone distance,

Now that the circular thickness has been converted to a

chordal thickness, a small correction is needed to the location of

the thickness in the profile direction (along yn). Figure 8 depicts

this correction and provides a visual explanation why this correction

is required. The working radius is equal to the pitch

radius in the figure, and its relative radius has been decreased to

exaggerate the size of the correction in the figure.

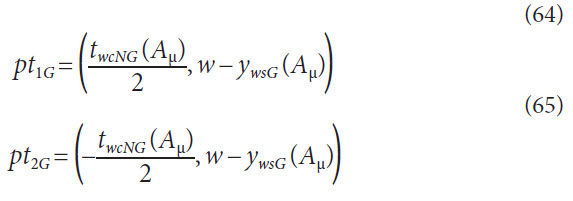

Pinion shift factor at working distance with respect to cone

distance,

Gear shift factor at working distance with respect to cone distance,

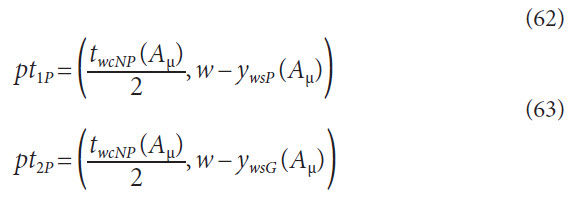

Local Cartesian coordinates for the pinion with respect to

cone distance,

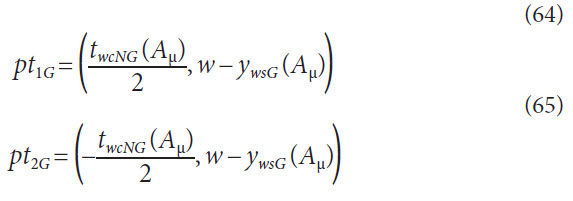

Local Cartesian coordinates for the gear with respect to cone

distance,

Transform the Local Normal Tooth Thicknesses to

Global

To this point all the tooth thickness points are defined relative

to a local coordinate system. The global location for each one

of these local coordinate systems are known, but to complete

the model, all points describing the tooth flanks must be known

relative to the global coordinate system. This is accomplished

using a coordinate transformation matrix, CT:

Figure 8 Shift factor when converting

circular to chordal thicknesses

(pinion shown).

Where,

CG is a 3×3 identity matrix that describes the global coordinate

system. See Coordinate System Definition for a more

detailed explanation. Once a vector, Vp, relative to the local coordinate system, Cn, is constructed that passes through a calculated

tooth flank point, the transformation can be calculated:

Where,

VG is a vector that passes through the exact same flank point,

but is described relative to the global coordinate system.

Results

Now that the method is complete, the next logical step is to

determine just how accurate this model is when compared to

the theoretical geometry of a spiral bevel gear. This method is

strictly approximate; many caveats have been discussed in the

previous sections. To accomplish a comparison between this

method and a theoretical part there must be a reliable standard

by which to compare it. Comparing the calculated points from

this method with a physical, cut part would introduce potential

variations from the manufacturing process. For this reason

alone it was decided to compare the calculated points to a different,

yet trusted, mathematical model. Gleason Works has developed

a commercial software package — T900 — that generates

an accurate point cloud describing the geometry of the tooth

flank and fillet condition of bevel gears and pinions. While the

purpose of this software is far greater than just the generation

of a point cloud, the other functionality is beyond the scope of

this document. The point cloud produced from T900 can be

imported into a CAD package to assist in the generation of the

exact geometry produced by the machine settings

for a particular design. The point cloud represents

the standard as to which this method is compared.

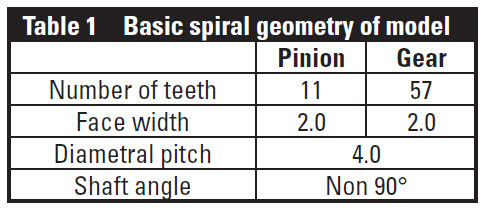

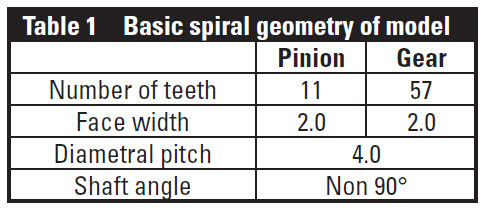

The member chosen for this analysis is a left-hand

spiral bevel gear generated by face mill completing.

Some of the basic geometry has been provided in

Table 1, but the exact details of the geometry are relatively

unimportant. An angular set was chosen as this

method has no shaft angle restrictions.

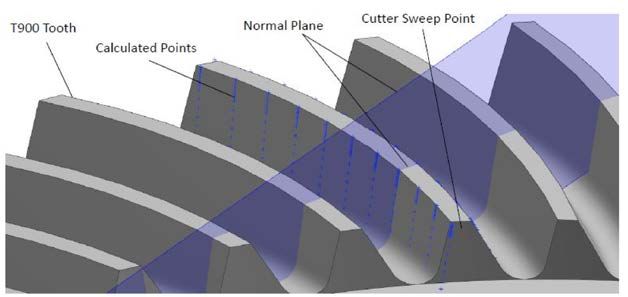

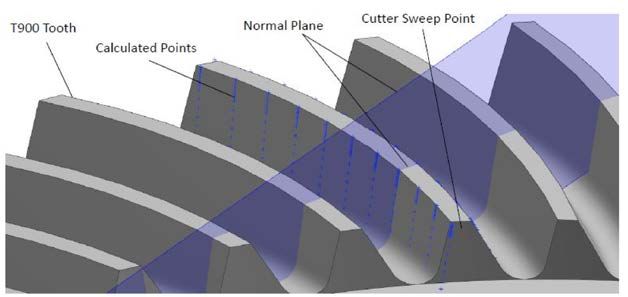

The output from T900 is a point cloud that

describes the flanks of a spiral bevel or hypoid gear

set. A gear tooth is divided into a 13- (profile) by-10

(length) grid for each flank; therefore 260 unique

points describe each tooth. For this analysis these

discrete points were bridged together using Siemens

NX 8.5 CAD software. The point cloud was connected

in the profile and lengthwise direction with

curves generated by a cubic, polynomial regression.

Once the lattice of curves is generated the curves

are used as ribs to create a bi-cubic surface. Figure

9 shows the tooth surface generated from the T900

point cloud in gray.

The face width of the part is broken into 10 segments

for the calculation; addendum and dedendum

are also broken into 10 segments. The part being modeled has a

short addendum and long dedendum. Figure 10 shows the calculated

points and solid model sectioned through the normal

plane (Fig. 9) of a tooth.

Figure 9 Calculated points overlaid on a tooth modeled using Gleason

T900.

Figure 10 Calculated points in the normal plane.

The calculated points go beyond the

root line of the model because the calculated points were generated

to the base circle radius of the virtual spur gear. When

doing the comparison the last four points of each profile will be

omitted, as they fall below the root fillet tangency point.

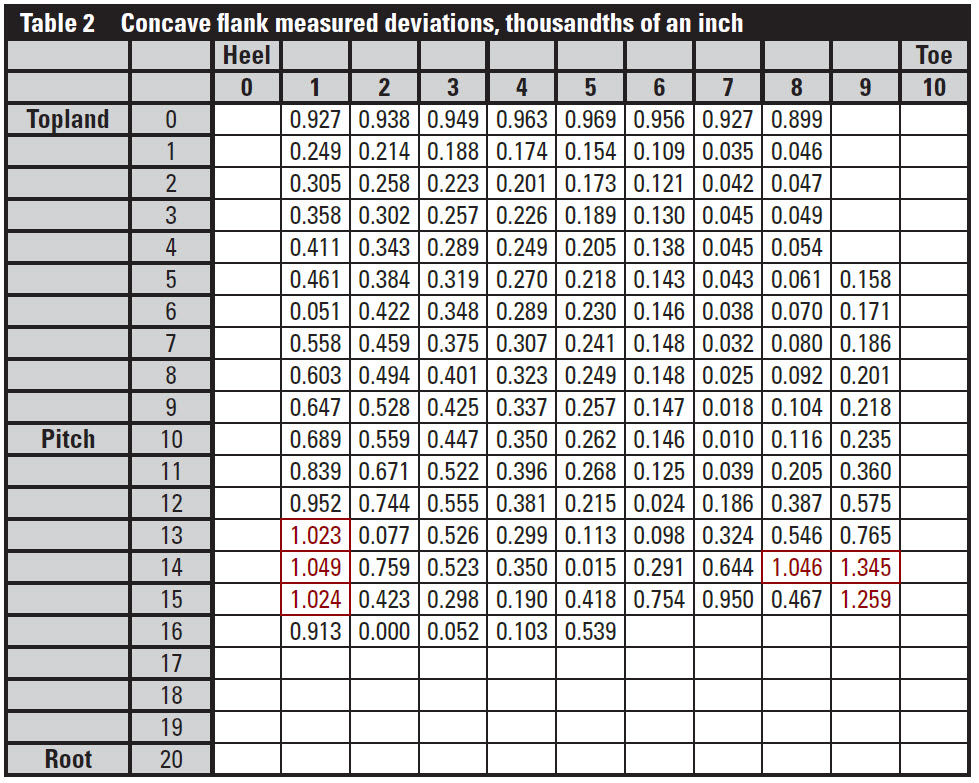

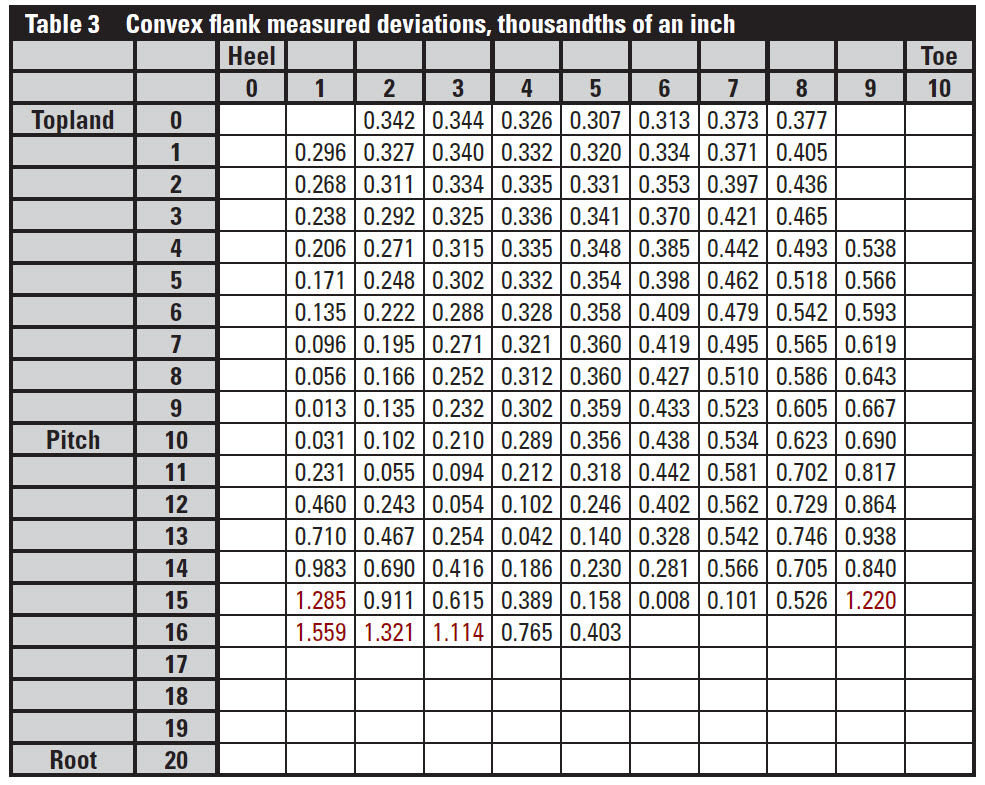

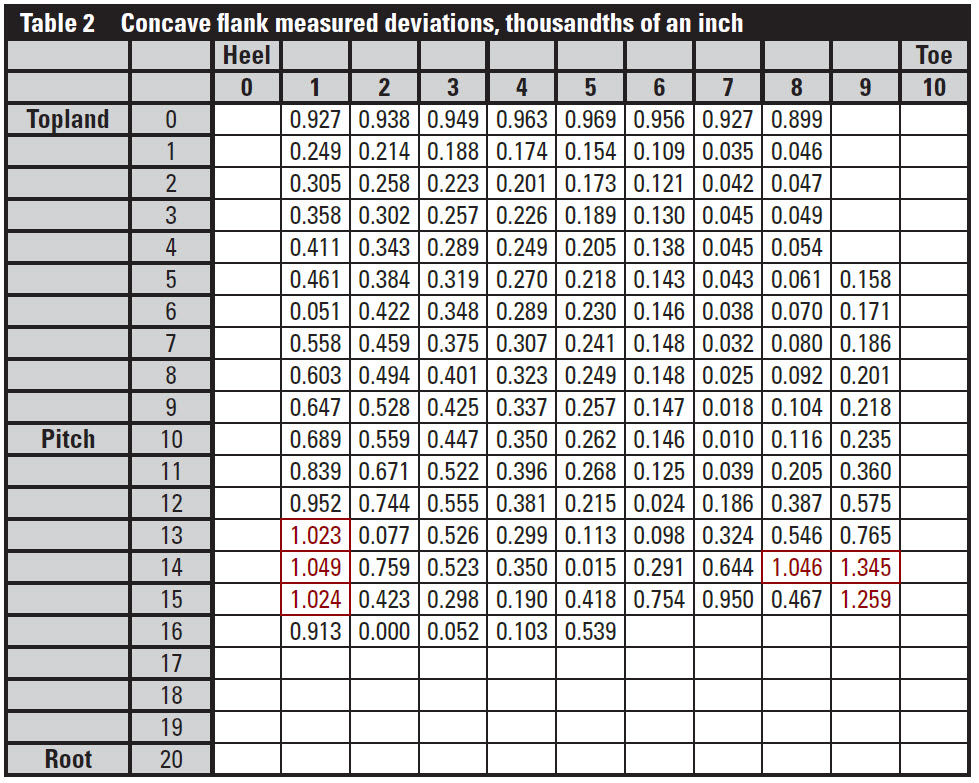

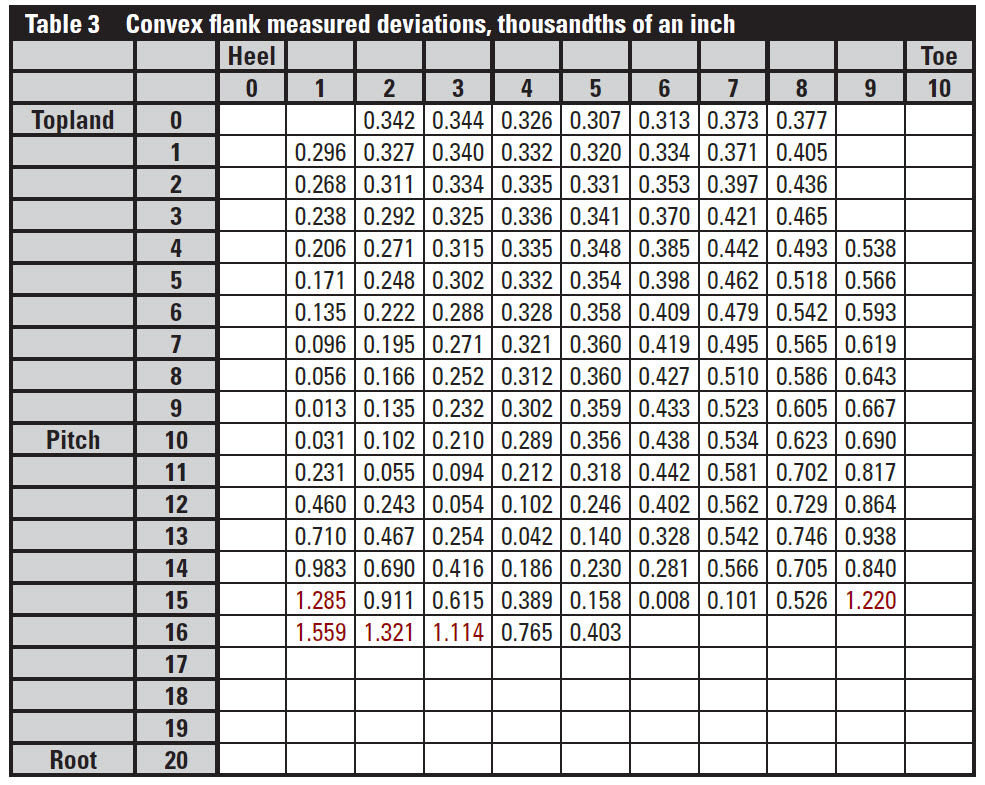

A linear measurement normal to the T900 surface to each calculated

point is used to measure the deviation between the calculated

points and the surface. The normal tooth thicknesses

at the toe and heel will be omitted in the comparison, as these

points are beyond the bounds of the T900 surface. The absolute

values of the measured deviations for each flank are given

(Tables 2 and 3).

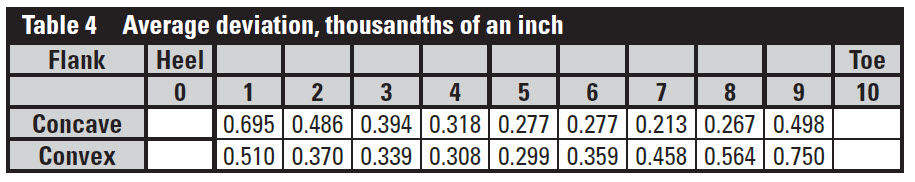

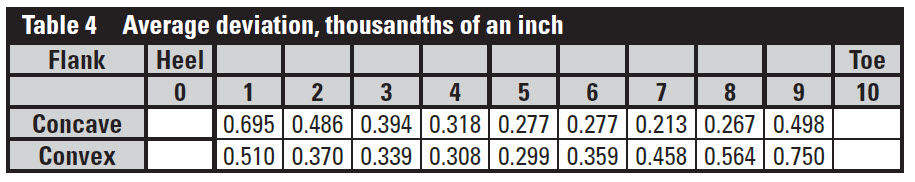

The red values are measured deviations that exceed one onethousandth

of an inch. Overall, the results depict a model that

very closely approximates the flanks predicted by the Gleason

Works T900 software. The average deviation for each normal

cross-section in the lengthwise direction is displayed in Table 4.

Conclusion

The purpose of this presentation is to describe a procedure for

calculating a very close approximation of the geometry of a spiral

bevel gear tooth.

This method is built upon the techniques and formulas

described in AGMA 929-A06.

The second portion of the document compared the results of

this method with the results from a proven Gleason software

package.

The results are extremely close.

Many models have been generated since this original case

study, and the subsequent models correlate well with the geometry

predicted by Gleason software.

The model described throughout this document

should not be used for advanced analysis

(i.e., finite element or the like), as the models

created from this method do not have any modifications

to the tooth flanks to adjust or optimize

the tooth contact pattern.

At present AGMA’s Bevel Gear Committee

is working on revising the formulas in AGMA

929-A06 to adopt the generalized formulas

described here. The technique of utilizing generalized

formulas will expand the capabilities of

AGMA 929.

After graduating from

Northern Illinois University

in 2010 with a bachelors’ in

mechanical engineering,

Brendan Bijonowski

has pursued a career in

design. In 2011 he joined the

engineering ranks of Arrow

Gear Company, located in Downers Grove,

IL as a design engineer. His passion for the

geometry of gearing and attention to detail can

clearly be seen in all of his work. Bijonowski is

a member of the AGMA Bevel Gear Committee,

where he works on defining geometry and

improving rating methods. He is also a

member of the AGMA Computer Programming

Committee, where he applies his experience

and knowledge as a gear engineer to an evergrowing

collection of technical software.

References:

- Baxter, Jr., M.L. Spiral Bevel Gear Theory, Unpublished.

1963.

- AGMA 929-A06. Calculation of Bevel Gear Top Land and

Guidance on Cutter Edge Radius.

- Colbourne, J.R. The Geometry of Involute Gears,

Springer-Verlag, New York, 1987.

- ANSI/AGMA 2005-D03. Design Manual for Bevel Gears.

- Grant, G.B. A Treatise on Gear Wheels, 21st Edition.

Philadelphia Gear Works Inc., Philadelphia, 1980.

- Khiralla, T.W. On the Geometry of External Involute Spur

Gears, C/I Leaming, North Hollywood, California, 1976.

- Krenzer, T. The Bevel Gear, 2007.

- Litvin, F.L. Theory of Gearing, NASA Reference

Publication; 1212 (AVSCOM Technical Report; 88-C-

035), 1989.

- NX 8.5 Help Documentation. Siemens Product Lifecycle

Management Software Inc., 2012.

1- Shtipelman, B.A. Design and Manufacture of Hypoid

Gears, John Wiley and Sons, Inc. 1978.

-

T900 User’s Manual. Gleason Works.

Figure 1 Visual depiction of calculation method.

Figure 1 Visual depiction of calculation method. Figure 2 Pitch cone.

Figure 2 Pitch cone. Figure 3 Generating triangle in pitch plane for face milling.

Figure 3 Generating triangle in pitch plane for face milling.

Figure 4 Generating triangle in pitch plane for face hobbing.

Figure 4 Generating triangle in pitch plane for face hobbing.

Figure 4 Generating triangle in pitch plane for face hobbing.

Figure 4 Generating triangle in pitch plane for face hobbing. Figure 4 Generating triangle in pitch plane for face hobbing.

Figure 4 Generating triangle in pitch plane for face hobbing.

Figure 7 Definition of the geometry of the virtual spur gear in the

normal plane.

Figure 7 Definition of the geometry of the virtual spur gear in the

normal plane.

Figure 8 Shift factor when converting

circular to chordal thicknesses

(pinion shown).

Figure 8 Shift factor when converting

circular to chordal thicknesses

(pinion shown).

Figure 9 Calculated points overlaid on a tooth modeled using Gleason T900.

Figure 9 Calculated points overlaid on a tooth modeled using Gleason T900. Figure 10 Calculated points in the normal plane.

Figure 10 Calculated points in the normal plane.

After graduating from

Northern Illinois University

in 2010 with a bachelors’ in

mechanical engineering,

Brendan Bijonowski

has pursued a career in

design. In 2011 he joined the

engineering ranks of Arrow

Gear Company, located in Downers Grove,

IL as a design engineer. His passion for the

geometry of gearing and attention to detail can

clearly be seen in all of his work. Bijonowski is

a member of the AGMA Bevel Gear Committee,

where he works on defining geometry and

improving rating methods. He is also a

member of the AGMA Computer Programming

Committee, where he applies his experience

and knowledge as a gear engineer to an evergrowing

collection of technical software.

After graduating from

Northern Illinois University

in 2010 with a bachelors’ in

mechanical engineering,

Brendan Bijonowski

has pursued a career in

design. In 2011 he joined the

engineering ranks of Arrow

Gear Company, located in Downers Grove,

IL as a design engineer. His passion for the

geometry of gearing and attention to detail can

clearly be seen in all of his work. Bijonowski is

a member of the AGMA Bevel Gear Committee,

where he works on defining geometry and

improving rating methods. He is also a

member of the AGMA Computer Programming

Committee, where he applies his experience

and knowledge as a gear engineer to an evergrowing

collection of technical software.