My Story – Bob Handschuh

Most of us only think of NASA with regard to the “S” [Space] in its acronym. The first “A” [Aerospace] is just as important to its mission of supporting the science of flight. NASA researchers like Mr. Handschuh have made major contributions to the field of aerospace gearing. — Chuck Schultz

For me it all started out when I was a youngster. I was always small in stature, and sports back then was very competitive, so even being picked to be on a team was not a sure thing. While I enjoyed playing different sports, I knew that this was not something for me to focus on.

However, at this early age I was always curious as to how mechanical things were put together and what made them work. First, I became pretty good at fixing and taking apart my bicycle. Next came the family’s lawn mower engine, and then I moved on to the family car and eventually my own cars.

I came from a post-World War II, blue collar family, so my education beyond high school was not expected nor encouraged. At this time in the early 1970s, a high school education was good enough; if you could land a job in a factory, you could earn a decent living. I ended up working in a few factory-type jobs that tended to be rather boring for me, and then an opportunity came up to work with a very close friend at his car repair business. Working with my hands on something mechanical, getting a chance to learn more about cars — and getting paid to do it — seemed like a good idea at the time.

Well, this was a fine situation for several years, until getting married and I started to look out farther than a week in the future. I began attending classes at our county’s community college part-time and found out that I liked what I was learning, for example — mathematics, physics, chemistry. This eventually led to attending college full-time, with my wife supporting both of us. During my time as an undergraduate, I was out of sequence for some courses, so I decided to see if I could land a co-op job. In checking into this at the university’s co-op office, I saw a flyer on their bulletin board that NASA Lewis Research Center was hiring co-ops. I inquired and found out that NASA had already hired all the co-ops that they needed, but if I wanted to go and meet with their co-op and higher education office person, the university would set up the meeting.

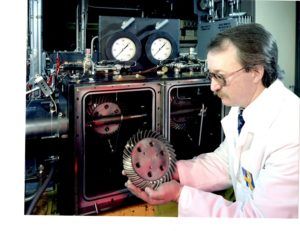

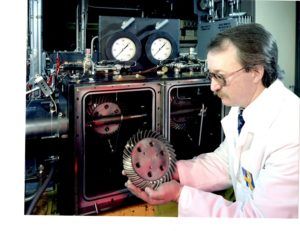

[caption id="attachment_2726" align="alignnone" width="300"]

Handschuh at NASA Glenn in 1992.[/caption]

During my visit, a senior researcher from the seals and rotordynamics section stopped in this office during my interview and was inquiring if there were any co-ops still available. This chance meeting ended up becoming the beginning of my career at NASA — first as a co-op, then being hired in as an Army researcher, and finally transferring back to NASA. This was a lesson in never giving up. Also, working for the government during this time, afforded me the opportunity to further my education. I took full advantage of this and went on to earn a Masters’ (1987) and Ph.D. (1993) in mechanical engineering.

As a new, full-time employee in 1982, I started conducting research on gas turbine seals and hoped that I would get to do some rotordynamics research. At that time there was a concerted effort to improve efficiency and performance of gas turbine engines (even today this is an important research area). I was tasked to work on high-temperature erosion of ceramics (particles that are ingested into the engine that wear away the seal and increase the turbine blade tip to seal clearance — thus decreasing efficiency). This work lasted for a few years, until there was a major center reorganization and certain areas had their research stopped.

This reorganization resulted in my transfer to a group that conducted basic and applied research on helicopter / aviation gearboxes. This transfer resulted in a 35 + year career in the gearing area.

Working in this mechanical engineering discipline was fun and rewarding; I was able to work with many brilliant and talented people at universities such as Professor Faydor Litvin at the University of Illinois/Chicago campus. Also, I was able to interact with the four USA helicopter manufacturers drive system R&D teams. Bridging the highly theoretical university grant activities with the future needs of the helicopter industry allowed me to work on many performance issues that are important to future aerospace drive systems.

Fortunately, I was able to travel to and participate in many conferences around the world and meet leading researchers from Europe and Asia. This exposure to what, why, and how others conduct R&D efforts was very beneficial to the projects we worked on at NASA.

Even now, in retirement, I am still very interested in the work going on in the gearing field. I have continued to work on some gearing-related issues I didn’t have time to do while working for NASA, and now have continued to work in this field as a part-time consultant.

Dr. Robert Handschuh has over 30 years of experience with NASA and Department of Defense rotorcraft drive system analysis and experimental methods. He has served as the Drive Systems team leader for the Tribology & Mechanical Components Branch at NASA Glenn Research Center in Cleveland, Ohio for over 15 years, and currently leads the research there in high-speed gearing, including windage, loss-of-lubrication technology, and hybrid gearing. Handschuh is credited with successfully developing many experimental research test facilities at Glenn, and has conducted testing in the following areas: high-temperature, ceramic seal erosion; blade-shroud seal rub; planetary geartrains; spiral bevel gears and face gears; high-speed, helical geartrains; single-tooth-bending fatigue; and high-speed gear windage. Handschuh retired from NASA Glenn earlier this year.

Handschuh at NASA Glenn in 1992.[/caption]

During my visit, a senior researcher from the seals and rotordynamics section stopped in this office during my interview and was inquiring if there were any co-ops still available. This chance meeting ended up becoming the beginning of my career at NASA — first as a co-op, then being hired in as an Army researcher, and finally transferring back to NASA. This was a lesson in never giving up. Also, working for the government during this time, afforded me the opportunity to further my education. I took full advantage of this and went on to earn a Masters’ (1987) and Ph.D. (1993) in mechanical engineering.

As a new, full-time employee in 1982, I started conducting research on gas turbine seals and hoped that I would get to do some rotordynamics research. At that time there was a concerted effort to improve efficiency and performance of gas turbine engines (even today this is an important research area). I was tasked to work on high-temperature erosion of ceramics (particles that are ingested into the engine that wear away the seal and increase the turbine blade tip to seal clearance — thus decreasing efficiency). This work lasted for a few years, until there was a major center reorganization and certain areas had their research stopped.

This reorganization resulted in my transfer to a group that conducted basic and applied research on helicopter / aviation gearboxes. This transfer resulted in a 35 + year career in the gearing area.

Working in this mechanical engineering discipline was fun and rewarding; I was able to work with many brilliant and talented people at universities such as Professor Faydor Litvin at the University of Illinois/Chicago campus. Also, I was able to interact with the four USA helicopter manufacturers drive system R&D teams. Bridging the highly theoretical university grant activities with the future needs of the helicopter industry allowed me to work on many performance issues that are important to future aerospace drive systems.

Fortunately, I was able to travel to and participate in many conferences around the world and meet leading researchers from Europe and Asia. This exposure to what, why, and how others conduct R&D efforts was very beneficial to the projects we worked on at NASA.

Even now, in retirement, I am still very interested in the work going on in the gearing field. I have continued to work on some gearing-related issues I didn’t have time to do while working for NASA, and now have continued to work in this field as a part-time consultant.

Dr. Robert Handschuh has over 30 years of experience with NASA and Department of Defense rotorcraft drive system analysis and experimental methods. He has served as the Drive Systems team leader for the Tribology & Mechanical Components Branch at NASA Glenn Research Center in Cleveland, Ohio for over 15 years, and currently leads the research there in high-speed gearing, including windage, loss-of-lubrication technology, and hybrid gearing. Handschuh is credited with successfully developing many experimental research test facilities at Glenn, and has conducted testing in the following areas: high-temperature, ceramic seal erosion; blade-shroud seal rub; planetary geartrains; spiral bevel gears and face gears; high-speed, helical geartrains; single-tooth-bending fatigue; and high-speed gear windage. Handschuh retired from NASA Glenn earlier this year.

Handschuh at NASA Glenn in 1992.[/caption]

During my visit, a senior researcher from the seals and rotordynamics section stopped in this office during my interview and was inquiring if there were any co-ops still available. This chance meeting ended up becoming the beginning of my career at NASA — first as a co-op, then being hired in as an Army researcher, and finally transferring back to NASA. This was a lesson in never giving up. Also, working for the government during this time, afforded me the opportunity to further my education. I took full advantage of this and went on to earn a Masters’ (1987) and Ph.D. (1993) in mechanical engineering.

As a new, full-time employee in 1982, I started conducting research on gas turbine seals and hoped that I would get to do some rotordynamics research. At that time there was a concerted effort to improve efficiency and performance of gas turbine engines (even today this is an important research area). I was tasked to work on high-temperature erosion of ceramics (particles that are ingested into the engine that wear away the seal and increase the turbine blade tip to seal clearance — thus decreasing efficiency). This work lasted for a few years, until there was a major center reorganization and certain areas had their research stopped.

This reorganization resulted in my transfer to a group that conducted basic and applied research on helicopter / aviation gearboxes. This transfer resulted in a 35 + year career in the gearing area.

Working in this mechanical engineering discipline was fun and rewarding; I was able to work with many brilliant and talented people at universities such as Professor Faydor Litvin at the University of Illinois/Chicago campus. Also, I was able to interact with the four USA helicopter manufacturers drive system R&D teams. Bridging the highly theoretical university grant activities with the future needs of the helicopter industry allowed me to work on many performance issues that are important to future aerospace drive systems.

Fortunately, I was able to travel to and participate in many conferences around the world and meet leading researchers from Europe and Asia. This exposure to what, why, and how others conduct R&D efforts was very beneficial to the projects we worked on at NASA.

Even now, in retirement, I am still very interested in the work going on in the gearing field. I have continued to work on some gearing-related issues I didn’t have time to do while working for NASA, and now have continued to work in this field as a part-time consultant.

Dr. Robert Handschuh has over 30 years of experience with NASA and Department of Defense rotorcraft drive system analysis and experimental methods. He has served as the Drive Systems team leader for the Tribology & Mechanical Components Branch at NASA Glenn Research Center in Cleveland, Ohio for over 15 years, and currently leads the research there in high-speed gearing, including windage, loss-of-lubrication technology, and hybrid gearing. Handschuh is credited with successfully developing many experimental research test facilities at Glenn, and has conducted testing in the following areas: high-temperature, ceramic seal erosion; blade-shroud seal rub; planetary geartrains; spiral bevel gears and face gears; high-speed, helical geartrains; single-tooth-bending fatigue; and high-speed gear windage. Handschuh retired from NASA Glenn earlier this year.