EMAG Presents E-Mobility and Digital Solutions at IMTS 2022

EMAG will highlight productive, and at the same time, flexible manufacturing solutions for electromobility at IMTS. Among other things, the focus is on the vertical pick-up lathes of the VL series, which EMAG now delivers IoT-Ready.

Whether electric drive, hybrid motor or conventional drive - production planners face the great challenge of developing diverse manufacturing solutions for the future. On the one hand, they need new manufacturing solutions for a wide variety of components; on the other hand, costs must be reduced, and production processes optimized.

EMAG is also aware of this challenge and therefore began investing in digital solutions in addition to processing technologies a few years ago. EMAG's customers now benefit from this investment in networked production, as the combination of highly productive manufacturing technology and data analysis opens up completely new ways of production planning and thus opportunities for cost optimization.

EMAG is convinced that the future belongs to data-optimized production. Optimizing cycle times and unit costs is important, but EMAG goes one step further and focuses on overall equipment efficiency (OEE) and its optimization based on manufacturing data. Through data analysis, unnecessary downtimes, due to component wear, for example, or, in the worst case, due to the failure of a machine, can be reduced or avoided altogether. Productivity increases of over 10 percent are the norm here. To make it as easy as possible for EMAG customers to enter the world of data-optimized production, the machines in the VL series are now delivered IoT-Ready. This means that the machines can be integrated directly into existing IoT networks with little effort. Specifically, this means that the machines are equipped with an EDNA IoT core (an IPC). This IPC is already installed and networked with the machine controller. In addition, the machines are equipped with the EDNA NEURON 3DG sensor technology (one or more acceleration sensors on the spindle and, if necessary, the y-axis), which enables regular automatic monitoring of the machine's health. Thus, data-optimized production can be started directly.

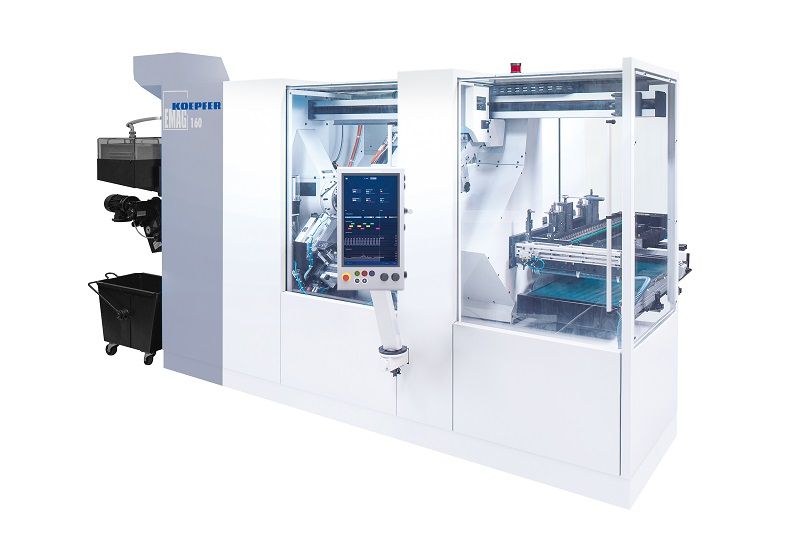

Three axes, a tool turret with up to twelve driven tools and integrated automation – these are the distinguishing features of all machines in the VL series. In addition to the standard FANUC control, this series can now be equipped with the new EDNA HMI – a touch panel that can be configured to meet a wide variety of requirements.

EMAG will show a VL 4 with the new panel so that IMTS visitors can see the innovative machine operation for themselves. Workpieces with a maximum diameter of up to 400 mm and a workpiece length of 300 mm can be machined on the vertical lathes of the VL series. Short chip-to-chip times are ensured by the integrated automation via pick-up spindle, which automatically removes the components to be machined from the lateral conveyor belt and feeds them to the work area. The turret below the work spindle accommodates up to twelve turning or driven tools. In addition, the lathes can be equipped with a y-axis in the turret to machine even more complex geometries.