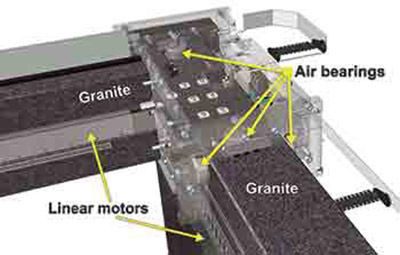

Granite has been used for highly accurate

CMMs and other measuring instruments

for many years. It offers a number

of benefits for accuracy-determining

components of industrial measuring

technology:

- Due to the age and origin, granite is

free of internal tensions and thus externally

stable in the long term

- The thermal expansion coefficient is

only about half that of steel and a quarter

of aluminum

- It is highly wear-proof, pressure-proof

and deforms 25% less under load than

an identical aluminum component – at

a higher specific weight of only about

5%

- Granite is non-magnetic, non-corroding,

and has vibration damping characteristics

- Proper processing produces nearly

pore-free, flat and level surfaces that

provide a solid basis for air bearing

guides — a well-established technology

that was a prerequisite for the ultimate

accuracy of coordinate measuring

equipment.

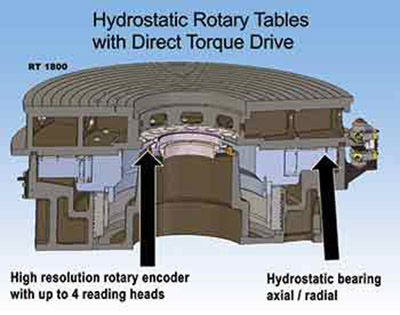

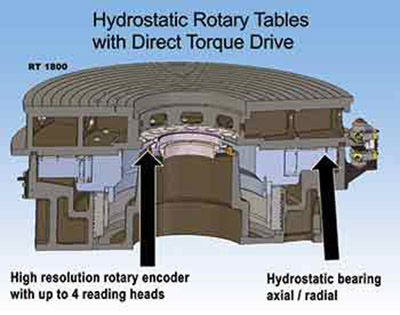

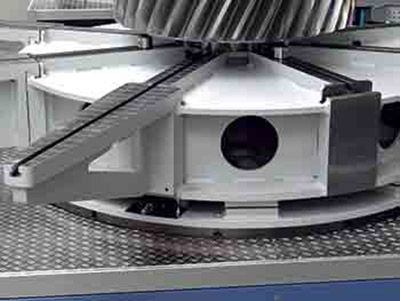

Hydrostatic rotary tables (Fig. 3) with

direct drive torque drive motors can provide

the precision required for measurement

of large diameters and heavy gears

up to 40,909 kg (90,000 lbs.). Hydrostatic

bearings have no metal-to-metal contact,

extremely low friction and virtually limitless

life. Conventional ball bearing tables

and air bearing tables typically have

much lower weight capabilities. These

well-proven and technically advanced

hydrostatic rotary tables are normally

used in large gear grinding machines.

Figure 3 Hydrostatic rotary table.

- Click image to enlarge

Special mechanical solutions for the

rotary table and specific control measures

are needed for measuring large gears in

respect to polar inertia. The machine

needs to be able to accurately position a

part weighing 40,000 kg as well as one

weighing as little as 28g (1 oz). In addition

to the part’s polar inertia, the inertia

of the equipment’s workpiece support has

to be considered. In order to determine

the actual conditions, the gear inspection

system needs to be capable of automatically

adjusting multiple drive parameters

in order to gain accurate and repeatable

measuring results. This is accomplished

through the use of intelligent algorithms

and intelligent drives.

A special design of rotary encoder is

used for this large application. It has a

large diameter and utilizes up to four

reading heads and double-scale interpolation

for enhanced accuracy.

Thermal Stability

The larger the component and the longer

the inspection time, the larger the change

in size as a result of temperature change.

By using granite for the machine guideways,

this change is minimized due the

low coefficient of expansion and granite’s

relatively slow rate of change.

To compensate for deviations caused

by temperature change, the equipment needs to provide several temperature sensors

for the machine and workpiece, and

corresponding algorithms to consider the

temperature effects on the evaluation of

measuring data.

For production efficiency, inspection

equipment is typically installed close to

the production facilities. Due to equipment

size and location, workpiece transportation

methods and paths often lead

to a working environment with temperature

swings. To meet this challenge, large

gear inspection equipment must have

long-term thermal stability, temperature

compensation and way covers.

To achieve this stability, the base plate

and at least the Y and Z linear axes (used

for the needed motion for generative gear

inspection) should be of granite construction

to take advantage of the material’s low

coefficient of expansion and resistance

to the effects of temperature. Each axis

has temperature measurement equipment

built in, and a probe is used on the part

to measure the temperature. This data is

used to compensate for the temperature of

the part and the machine’s axes.

The ways are covered and create a

microclimate effect, which reduces temperature

variation. This damps rapid

transient fluctuations in temperature.

On large systems, these way covers are

also walkways for operator access to the

machine and workpiece.

Vibration Control

Rather than relying on an expensive special

foundation, a modern large gear

inspection system employs an active,

computer controlled, air suspension system

(Fig. 4). This isolates the machine

from vibrations in the shop environment

and keeps the machine constantly level.

This technology has been long proven

in high accuracy CMM applications for

many years.

Figure 4 Air suspension vibration isolation.

- Click image to enlarge

A concrete floor or foundation is subject

to changes over time. Rather than

relying on the foundation or floor for

stability, a large gear measuring system

requires intrinsic stability independent of

the floor or foundation.

In addition to the stability it provides,

the active air suspension, with its effective

isolation, can substantially reduce

installation cost and allow more freedom

in locating the machine.

Mounting and Centering

In stark comparison to small gears,

large workpieces (externals or internals)

require intelligent, operator-friendly solutions

for safely mounting and centering

the parts. It is no longer necessary

or acceptable to use a huge hammer or

swinging ram to center heavy parts. Once

mounted, the system completes the fully

automatic procedure to determine the

axis of the workpiece.

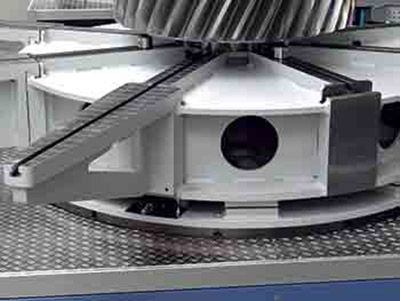

Figure 5 shows a leveling table with a

cross-slide and the possibility to extend

the mounting range by means of extension

arms (spider).

Figure 5 Mounting and centering.

- Click image to enlarge

The mounting and centering a heavy

part can be accomplished in four steps:

- Mount 3 “fix points” on the table in

positions provided by the machine

using built-in utilities

- Load part on the leveling table against

or near fix points for pre-positioning

- The system will automatically probe

the actual position of the part to determine

the needed movements of the

cross-slide

- Move the cross-slide axis by means of

monitoring the actual position on the

screen, shown in real time by the operator

software

In addition to the ease of use this provides,

a substantial time savings and efficiency

improvement is also realized. It is

also safer for operators and can reduce

the chance of damage to the part.

Safety

To protect operators from accidents

during the measurement process, large

gear inspection machines must provide

additional safety features not needed on

small- or medium-size machines. These

safety systems must be standard equipment

because safety is required and not

optional.

A PC-based intelligent laser system

(Fig. 6) allows customizable safety zones

around the machine and exclusion zones

for fixed areas like room columns. Signal

lights indicate the status of the machine.

If there is movement into the protected

area, layers of increasing audible and visible

warnings precede the last warning

with horn, and finally, an emergency stop

will occur.

Figure 5 Mounting and centering.

- Click image to enlarge

Customized Versions – One Size

Does Not Fit All

Any gear measuring machines for workpieces

with diameters of 1,600 mm

and larger should fulfill all individual

demands of the customers and special

requests of the operators.

To provide this customization, R&P

Metrology GmbH uses modular design

by which individual machines are configured:

- Individualized design and size of granite

base plate to fit into existing facility

- Several options for vertical measuring

lengths

Rotary tables with different load capacities

using air bearings or hydrostatic

bearings as appropriate

Various tailstock lengths in fixed or

movable positions

Intelligent solutions for centering,

holding and clamping workpieces

Complete software library including

3-D software packages

Big Gears Require Special

Solutions

From the above discussion, it is clear

that large gear metrology requires careful

application of appropriate technologies

rather than just “supersizing” a standard

smaller gear checker.

Taken together as a system, the use of

intelligent algorithms for automatically

determining and controlling polar inertia,

granite guideways and air bearings,

hydrostatic rotary tables, thermal stability/

compensation and vibration isolation

combine to form the benchmark for

the current state-of-the-art in large gear

metrology. Controlling the large masses

involved, thermal stability, part centering

and alignment, safety and customization

all need to be taken into consideration and

addressed to produce accurate and reliable

gear inspection systems for large gears

About Author

Dwight Smith is the

Sales Manager for Kapp

Technologies, and product

manager for the R&P

Metrology line of large

gear measuring equipment,

which Kapp Technologies

distributes in North America.

He has over twenty-five years of experience

in the gear industry and gear metrology.

He chairs an AGMA committee and is an

instructor for the AGMA Basic Gear School,

and presents at the annual Kapp Niles Rocky

Mountain Gear Finishing School. For more

information about R&P Metrology machines

please contact Dwight Smith at 734-516-1365.