Metal Cutting Robots

Kadia Offers Deburring Robot Cells for Gear and General Machining Requirements

Kadia has been designing deburring robot cells based on 6-axis industrial robots for many years. In the meantime, a new trend is now emerging, solutions with an even higher value-added component, i.e., with general machining processes such as milling, drilling or thread cutting. The robot is thus no longer just part of a deburring machine.

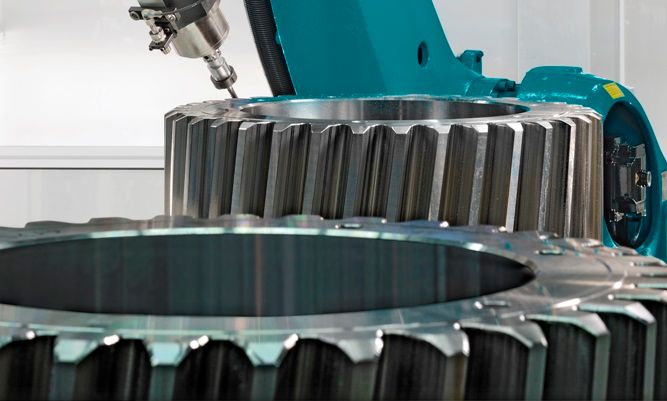

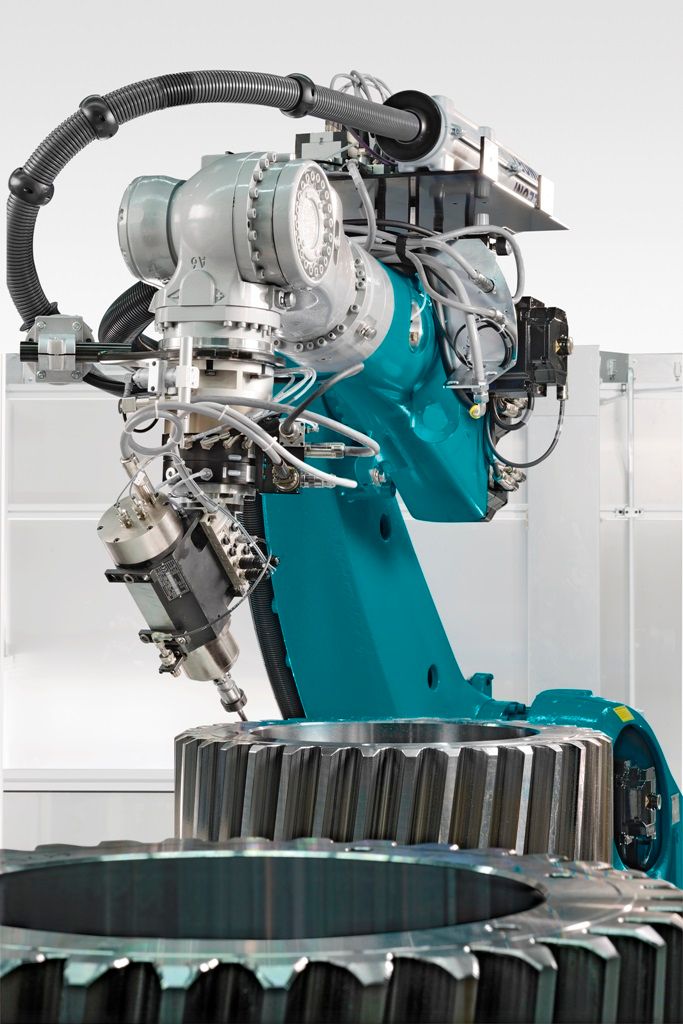

Figure 1: Using solid-carbide cutters, the robot provides the teeth with chamfers of up to 5 mm. It follows the involute contour of the tooth flanks exactly. Images by Kadia

Figure 1: Using solid-carbide cutters, the robot provides the teeth with chamfers of up to 5 mm. It follows the involute contour of the tooth flanks exactly. Images by Kadia

The Nürtingen-based company pursues two concepts with its Deburr-Robot-Cells: Either the robot grips the workpiece and moves it to fixed tools — often brushes — or it guides the tools itself, such as milling tools. The latter case is the bigger challenge. One example is the deburring of large gears (Fig. 1). The term deburring is no longer quite appropriate for this application; it is more a matter of edge shaping. The gears are given chamfers of up to 5 mm. The tool used for this is a solid carbide end mill. Programming is complex because the cutters follow the involute contour of the tooth flanks.

A further development in recent years has been Deburr-Automation-Cells in which the robot performs comprehensive handling tasks in addition to deburring. In this constellation, for example, it works together with machining centers, i.e., it places the components, removes them again and, if necessary, also acts as an interface for neighboring system parts such as quality or washing stations. Deburring is then just one task among several.

And these tasks are joined by others. That’s why Kadia is now offering a third category of robot systems as an application: Machining-Robot-Cells. "More and more customers are asking whether it is possible with the robot, for example, to also apply a thread or a flat surface," explains Jannik Weiss from deburring machines sales at Kadia. The customers' plan: They want to avoid reclamping operations. If the deburring robot, which often continues the process chain after mechanical processing, can take work away from the other processing machines, a lot of time can possibly be saved. "We are repositioning ourselves a bit as a result," explains Henning Klein, managing director at Kadia. "Since we have accumulated many years of know-how with our automation solutions with robots or with our Deburr-Robot-Cells, the step to becoming a supplier for robot-assisted mechanical processing is no longer a big one."

Cost-effective machining solution