Fatigue Strength and Service Calculation of Gears

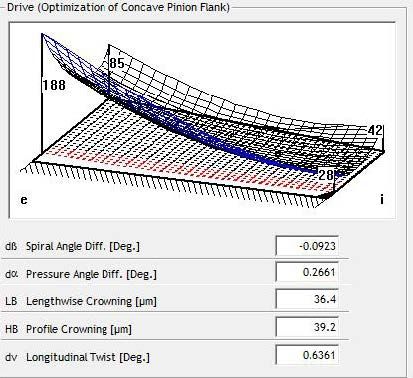

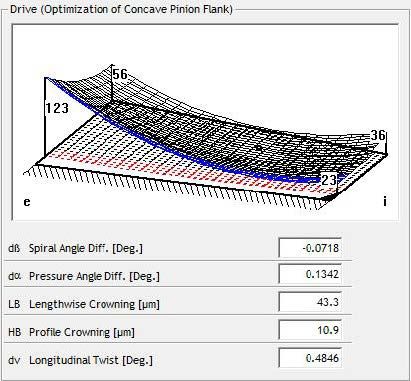

Bevel gear design is well-established. Flank geometry optimization is used worldwide to ensure satisfactory low-noise emissions and specific values for surface and bending stress.

But what about calculating the service life of gears? To its familiar KIMoS (Klingelnberg Integrated Manufacturing of Spiral Bevel Gears) software package, Klingelnberg has added a module for calculating the service life of a bevel or hypoid gear set that is based on the latest R&D work in service life calculation.

Designing bevel gears is a rather complex task. Unlike cylindrical gears, bevel gears are always designed in pairs. The design engineer must take numerous conflicting objectives into account, including minimum dimensions, maximum load capacity, noise reduction, and ease of manufacture on shop floor machines.

But one aspect is often left out: What about the gear’s fatigue strength?

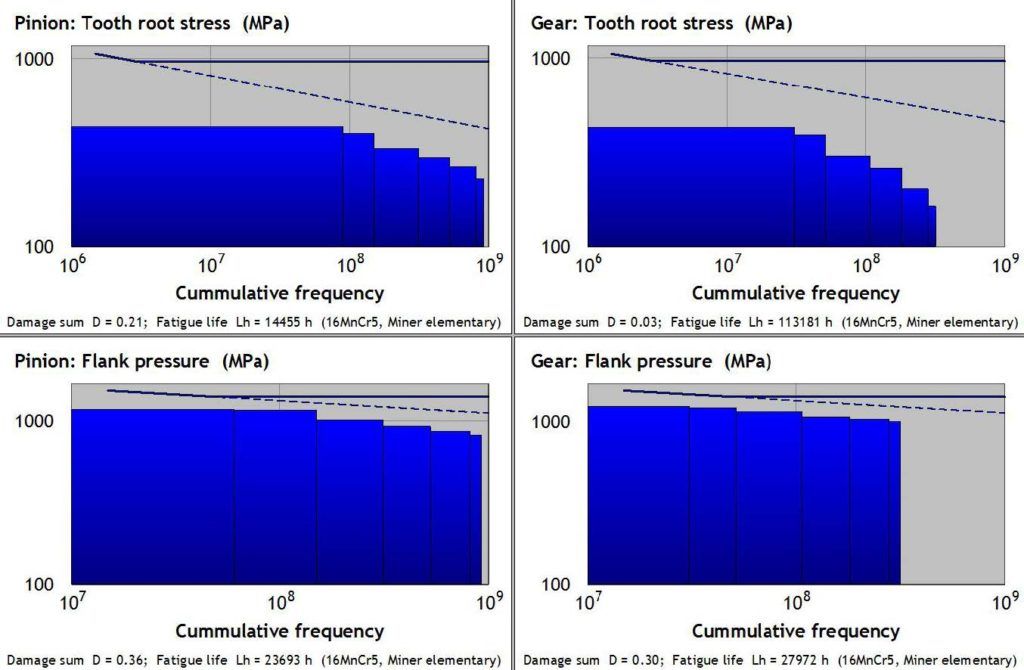

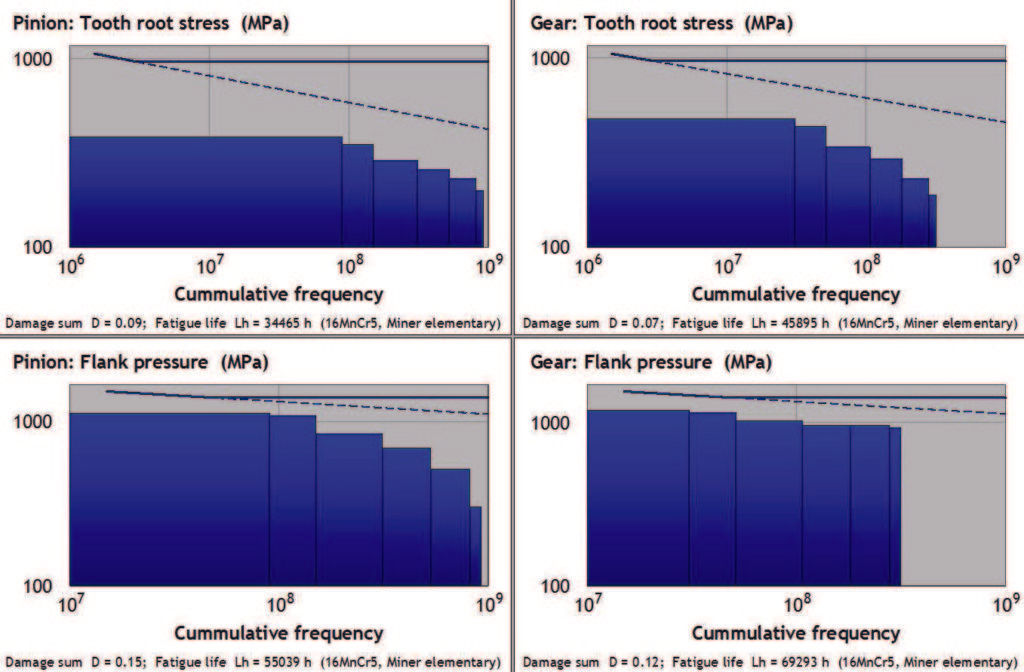

If the maximum load on a tooth does not exceed the load limits of the material, the tooth returns to its initial state after the load is removed. This assumption is valid for several hundred load applications. But when we are talking about several million load applications, damage will occur at much lower loads than the load limits of the material. This phenomenon is known as fatigue.

Fatigue strength testing – a core competence of OEMs and Tier 1 gear suppliers – is accomplished through time-consuming testing of transmissions. These tests are performed with an empirically defined load spectrum that inflicts the same damage that would occur under practical service conditions. One of the machines used for these endurance tests on bevel gears is the Oerlikon TS 30 bevel gear test stand.